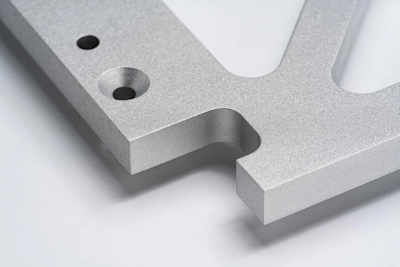

At GCH Process, we specialize in providing top-tier custom aluminum machining services. Our advanced CNC machines, equipped with powerful spindles and high-RPM capabilities, enable us to deliver high-precision parts with rapid turnaround times. Whether you need a simple enclosure or a complex aluminum reflector, our machining solutions are designed to meet your specific needs.

Why Choose GCH Process for Custom Aluminum Machining?

1. No Minimum Order Quantity (MOQ)

We cater to all project sizes, from one-off prototypes to large production runs, ensuring flexibility for all our clients.

2. Competitive Pricing

Our efficient machining processes and cutting-edge technology allow us to offer competitive prices without compromising on quality.

3. Fast Delivery

With a fleet of 40 advanced CNC machines, we can expedite your project from initial design to final delivery faster than many competitors.

4. Experienced Engineers

Our team comprises seasoned professionals with extensive experience across various industries, capable of handling the most complex projects.

5. High Precision and Tight Tolerances

We serve industries like aerospace and medical, providing parts with extremely tight tolerances using precise tooling and sophisticated CNC equipment.

6. Diverse Finishing Options

We offer a wide range of coatings and finishes to meet your specific project requirements, enhancing both functionality and aesthetics.

The Benefits of Custom Aluminum Machining

Aluminum is a preferred material in CNC machining due to its unique properties:

- Lightweight: Aluminum’s low density (2.7 g/cm³) makes it ideal for applications requiring reduced weight without sacrificing strength.

- Corrosion Resistance: Its natural resistance to oxidation, combined with various finishes, ensures long-lasting durability.

- Excellent Conductivity: Aluminum’s thermal and electrical conductivity makes it suitable for a variety of electrical and heat dissipation applications.

- Ease of Machining: Aluminum can be easily shaped, drilled, and folded, allowing the creation of complex geometries with high precision.

- Temperature Resistance: Unlike many materials, aluminum maintains its integrity at low temperatures, making it versatile for various environments.

Custom Aluminum Machining Capabilities at GCH Process

Our CNC machining capabilities cover a broad spectrum of processes to cater to diverse industry needs:

1. CNC Milling

Our high-speed CNC mills with multi-axis capabilities can handle complex parts, ensuring high precision and excellent surface finish.

2. CNC Turning

Ideal for producing symmetrical parts, our CNC turning machines are perfect for crafting detailed cylindrical components with tight tolerances.

3. CNC Drilling

We offer precise drilling solutions, including spot drilling and peck drilling, to create accurate and clean holes in aluminum parts.

4. Electrical Discharge Machining (EDM)

For intricate shapes and hard materials, our EDM machines provide exceptional precision, making them suitable for complex molds and dies.

5. CNC Plasma Cutting

Our CNC plasma cutters deliver fine cuts with excellent precision, ideal for creating detailed parts with minimal material waste.

6. CNC Grinding

For post-processing, our CNC grinders ensure a smooth, polished finish, enhancing the functionality and aesthetic of aluminum parts.

Aluminum Alloys We Work With

We machine a wide range of aluminum alloys, each selected for its specific properties:

- 6061 Aluminum: Versatile and widely used for structural components, electronic parts, and more due to its excellent machinability and strength.

- 7075 Aluminum: Known for high strength, it is often used in aerospace and high-stress applications.

- 2024 Aluminum: Offers a high strength-to-weight ratio, commonly used in aviation.

- 5052 Aluminum: Highly corrosion-resistant and formable, ideal for marine applications.

- 6063 Aluminum: Preferred for architectural applications due to its superior corrosion resistance.

- MIC6 Aluminum: Stress-relieved cast aluminum for tight tolerance applications, commonly used in precision machine tables and tooling.

Applications of Custom Aluminum Machining

Our custom aluminum machining services cater to a variety of industries:

1. Automotive: Custom brackets, engine components, and prototype models. 2. Aerospace: Structural components, turbine blades, and landing gear parts. 3. Medical: Surgical instruments, orthopedic implants, and diagnostic equipment parts. 4. Electronics: PCB enclosures, heat sinks, and custom sensor housings.

Ensuring Quality and Precision

At GCH Process, we are committed to delivering the highest quality products. Our in-house quality control measures include the use of HAAS 5-axis mills, Hexagon CMMs, and Olympus XRF analyzers to ensure each part meets stringent specifications.

Our Process:

- Design and CAD Modeling: Detailed 3D engineering designs are created to meet precise requirements.

- CAM and CNC Programming: Our CAM software generates optimal tool paths, ensuring high precision.

- Machine Setup: Proper tool and workpiece setup ensure stability and accuracy.

- Machining: Real-time adjustments and fine-tuning guarantee the final product meets all specifications.

- Post-Processing and Finishing: Grinding, deburring, and surface treatments enhance the final product’s quality.

Why GCH Process?

With our advanced capabilities and commitment to excellence, GCH Process is your ideal partner for custom aluminum machining projects. Whether you need a single prototype or a large production run, we deliver precision, quality, and efficiency every time.

Contact us today to discuss your project and discover how we can help you achieve your manufacturing goals with our custom aluminum machining services.