What is CNC Milling?

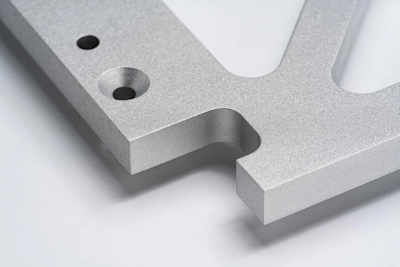

CNC milling is a precision manufacturing process that utilizes a rotating cutting tool mounted on a spindle to remove material from a workpiece. The workpiece is secured on a table, which moves or rotates along different planes, allowing the tool to machine from multiple angles. Advanced CNC milling machines can feature 5 or more axes of motion, enabling the production of complex geometries with high accuracy.

How Does CNC Milling Work?

CNC milling is a subtractive manufacturing process where a block of material, typically metal or plastic, is fixed inside the CNC machine. The machine uses G-code to control the movements of the cutting tool, which mills out the part from the raw material. The process leaves visible tool marks on plastic parts, whereas metal parts can undergo various finishing processes such as anodizing or chromate plating. After milling and finishing, the parts are packaged and shipped.

Metals Used in CNC Milling

CNC milling can process a wide range of metals, each with specific properties suitable for different applications. Here are some common metals and their properties:

| Material Name | Grade | Ultimate Tensile Strength (MPa) | Elongation at Break (%) | Hardness (HRB) | Chemical Resistance |

|---|---|---|---|---|---|

| ألومنيوم | 6061-T6 | 291-320 | 12-17 | 60 | High |

| ألومنيوم | 7075-T6 | 430-580 | 3-11 | 80 | Moderate |

| ألومنيوم | 7050 | 500-550 | 11 | 147 | Good |

| الفولاذ المقاوم للصدأ | 304/304L | 480-620 | 45-60 | 75-83 | Good |

| الفولاذ المقاوم للصدأ | 316/316L | 480-620 | 30-50 | 75-83 | Excellent |

| Tool Steel | D2 | 2100-2500 | 13-15 | 58-64 | Excellent |

| Brass | C360 | 140 | 23 | – | Moderate |

| النحاس | 110 | 220-230 | 15-50 | 40 HRF | Moderate to Poor |

Plastics Used in CNC Milling

Various plastics are used in CNC milling, each offering different properties for specific applications. Common plastics include:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Flexural Strength (MPa) | Wear Resistance | Elongation at Break (%) | Heat Resistance (°C) | Cost |

|---|---|---|---|---|---|---|---|

| ABS | 1.04 | 37 | 67 | Poor | 8 | 80 | $ |

| PC | 1.2 | 75 | – | Poor | 75 | 110 | $$ |

| Nylon 6/66 | 1.15 | 80 | 100 | Excellent | 50 | 90 | $$$ |

| POM (Delrin) | 1.39 | 67 | – | Good | 28 | -50/110 | $$ |

| PTFE | 2.16 | 26 | – | Good | 300 | -150/250 | $$$$ |

| PEEK | 1.32 | 115 | 170 | Excellent | 16 | 250 | $$$$ |

Types of CNC Milling Machines

CNC milling machines come in various configurations, each suited for different types of work:

- 3 Axis Milling Machine: Utilizes X, Y, and Z axes for a wide variety of tasks.

- 4 Axis Milling Machine: Adds a vertical axis rotation for more continuous machining.

- 5 Axis Milling Machine: Incorporates two additional rotary axes, allowing for machining on five sides of a workpiece without repositioning.

Available Surface Finishes for CNC Milling

Various surface finishes are available to enhance the appearance and functionality of machined parts:

- As Machined: Minor tool marks are visible.

- الطلاء بأكسيد الألومنيوم: Provides corrosion resistance, increased surface hardness, and heat dissipation. Available in various colors.

- Painting & Color Matching: Custom colors and finishes, including glossy and matte options.

- Blasting & Polishing: Creates a smooth, uniform surface by removing tool marks.

- Black Oxide: Improves corrosion resistance and reduces light reflection.

- التنظيف بالفرشاة: Increases surface hardness and wear resistance.

- Vapor Polishing: Achieves optical clarity on polycarbonate (PC) plastics.

- Heat Treatments: Includes annealing, carburizing, cryogenic treatment, induction hardening, and nitriding.

Advantages of Custom Aluminum Machining

Aluminum is highly favored in CNC machining due to its workability, strength, and versatility. Here are some key advantages:

- Light Weight: Ideal for applications where weight reduction is critical.

- Anti-Corrosive Qualities: Naturally resistant to corrosion, which can be enhanced with finishes.

- Conductivity: Excellent thermal and electrical conductivity.

- Convenient Machining: Easy to shape, drill, and form, allowing for complex designs.

- Temperature Resistance: Maintains properties at low temperatures, providing flexibility in the machining process.

Products Made with Custom Aluminum Machining

Common products made from various grades of aluminum include:

- Aluminum 6061: Versatile alloy used in structural components, electronic parts, and aircraft.

- Aluminum 7075: High-strength alloy for aerospace components and high-stress applications.

- Aluminum 2024: Used for applications requiring high strength-to-weight ratios.

- Aluminum 5052: Ideal for marine environments due to its corrosion resistance.

- Aluminum 6063: Known for its excellent corrosion resistance and formability.

الخاتمة

At GCH Process, we offer comprehensive CNC milling services in China, leveraging advanced technology and a wide range of materials to meet the precise needs of our clients. Our expertise in custom aluminum machining ensures high-quality, cost-effective solutions for various industries. Contact us today to discuss your CNC milling project and experience the GCH Process difference.