In the highly competitive consumer product market, speed, innovation, and precision are critical to success. CNC machining services have become a key enabler of these factors, providing the tools necessary to transform ideas into market-ready products. This article explores the role of CNC machining services in consumer product design, highlighting their benefits, the process, and how they contribute to bringing innovative products to market faster.

The Role of CNC Machining in Consumer Product Design

CNC machining services are integral to the design and development of consumer products, offering several advantages that make them a valuable tool for product designers and manufacturers:

Prototyping: CNC machining services allow for the rapid creation of prototypes, enabling designers to test and refine their concepts before moving into full-scale production. This is essential for ensuring that the final product meets consumer expectations and performs as intended.

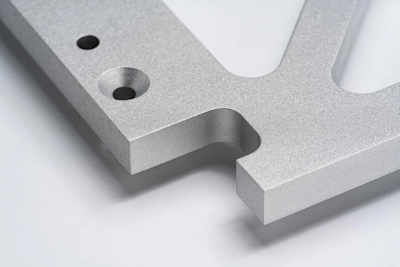

Precision and Detail: Consumer products often require intricate details and high precision to achieve the desired look and functionality. CNC machining services can produce these details with tight tolerances, ensuring that every product is of the highest quality.

Customization: In a market where personalization is increasingly important, CNC machining services offer the flexibility to create custom products tailored to individual consumer preferences. This includes custom engravings, unique designs, and one-of-a-kind components.

Material Versatility: CNC machining services can work with a wide range of materials, from metals and plastics to composites and ceramics. This versatility allows designers to choose the best materials for their products, whether for aesthetic, functional, or cost considerations.

The CNC Machining Process in Consumer Product Design

The process of using CNC machining services in consumer product design typically involves several key steps:

Concept Development: The first step in the design process is developing a concept for the product. This involves brainstorming ideas, sketching designs, and creating a vision for the final product.

CAD Modeling: Once the concept is developed, it is translated into a detailed CAD (Computer-Aided Design) model. This digital model serves as the blueprint for the CNC machining process, defining the product’s dimensions, features, and materials.

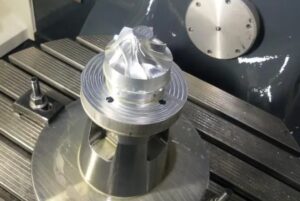

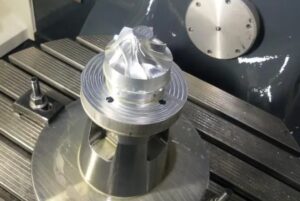

Prototyping and Testing: CNC machining services are used to create a physical prototype of the product. This prototype is then tested for functionality, performance, and consumer appeal. Any necessary adjustments are made based on feedback and testing results.

Design Refinement: Based on the testing results, the design is refined to address any issues and improve the product’s performance and aesthetics. This may involve adjusting dimensions, materials, or features to better meet consumer needs.

Final Production: Once the design is finalized, CNC machining services are used to produce the final product. This may involve creating molds for mass production, machining individual components, or producing custom parts for limited-edition products.

Benefits of CNC Machining in Consumer Product Design

The use of CNC machining services in consumer product design offers several key benefits:

Speed to Market: CNC machining allows for the rapid production of prototypes and final products, reducing the time it takes to bring a product to market. This speed is essential in a competitive market where being first to market can be a significant advantage.

Cost-Effectiveness: While CNC machining can have higher initial costs compared to other manufacturing methods, it offers cost savings in the long run due to its precision, accuracy, and ability to produce high-quality products with minimal rework.

Design Flexibility: CNC machining services offer the flexibility to create a wide range of products, from simple designs to complex, custom pieces. This flexibility is particularly valuable in the consumer product market, where innovation and differentiation are key to success.

Quality and Consistency: CNC machining ensures that every product is produced to the highest standards of quality and consistency. This is crucial in the consumer product market, where brand reputation and consumer satisfaction are directly tied to product quality.

Case Studies: CNC Machining in Consumer Product Design

The following case studies illustrate how CNC machining services have been used in the design and development of consumer products:

Smart Home Devices: A company developing smart home devices used CNC machining services to prototype and produce enclosures and components for their products. The precision and quality of CNC machining ensured that the devices had a sleek, modern design and performed reliably in the home environment.

Wearable Technology: A startup in the wearable technology space used CNC machining services to create custom housings for their fitness trackers and smartwatches. The ability to produce prototypes quickly allowed the company to iterate on their designs and bring their products to market faster.

Luxury Goods: A luxury goods manufacturer used CNC machining services to create high-end, custom-designed jewelry and accessories. The precision and detail provided by CNC machining allowed the company to offer unique, personalized products that appealed to discerning consumers.

The Future of CNC Machining in Consumer Product Design

As consumer preferences and market trends continue to evolve, CNC machining services will play an increasingly important role in product design and development. Key trends shaping the future of CNC machining in consumer products include:

Personalization and Customization: The demand for personalized and customized products will continue to grow, driving the need for CNC machining services that can produce one-of-a-kind items with high precision and quality.

Integration with Digital Design Tools: The integration of CNC machining with digital design tools, such as CAD and 3D printing, will enhance the design process, allowing for greater creativity and innovation in consumer products.

Sustainable Design: As consumers become more environmentally conscious, there will be a greater emphasis on sustainable product design. CNC machining services will play a key role in creating products that use sustainable materials, minimize waste, and have a lower environmental impact.

Advanced Materials: The development of new, advanced materials will drive the need for CNC machining services capable of working with these materials. This includes the use of lightweight, durable, and environmentally friendly materials in consumer products.

الخاتمة

CNC machining services are a vital tool in consumer product design, providing the speed, precision, and flexibility needed to bring innovative products to market. By enabling rapid prototyping, customization, and high-quality production, CNC machining services help companies stay competitive in a fast-paced market.

As consumer preferences and market trends continue to evolve, CNC machining services will play an increasingly important role in shaping the future of consumer products. Whether in smart home devices, wearable technology, or luxury goods, CNC machining is at the forefront of turning ideas into reality, helping companies create products that meet the needs and desires of modern consumers.