CNC (Computer Numerical Control) machining is a transformative manufacturing process where pre-programmed computer software dictates the movement of machinery and tools in a factory setting. This application automates various manufacturing techniques such as milling, water jet cutting, and laser cutting. Instructions are input into the CNC machine via a CAD file, which is then converted into a precise set of sequential commands. The CNC machine executes these programmed directives automatically, eliminating the need for a physical operator. التصنيع الآلي باستخدام الحاسب الآلي offers manufacturers numerous advantages, including cost reduction, increased speed, enhanced accuracy, and improved productivity.

Understanding CNC Machine Axes

The term “axes” in CNC machining refers to the different directions in which the machine can move. CNC machining involves the removal of material from a workpiece to achieve the desired shape. These machines typically operate along at least three axes: X (vertical), Y (horizontal), and Z (depth). A 4-axis machine includes an additional A axis (rotation around the X axis), and a 5-axis machine includes a B axis (rotation around the Y axis).

The number of axes a CNC machine possesses determines the complexity of the work it can perform, the level of detail it can achieve, and the variety of workpiece orientations it can manipulate. Here’s a deeper look into the distinctions between 3-axis, 4-axis, and 5-axis CNC machines.

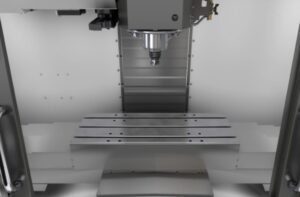

3-Axis CNC Machines

3-axis machining involves the cutting tool moving along the XYZ plane while the workpiece remains stationary. This method is ideal for parts that do not require extensive depth or intricate detailing. Common applications of 3-axis machining include:

- Automatic/Interactive Operation: The machine can be programmed to perform tasks with minimal human intervention, making it suitable for high-volume production runs.

- Milling Slots: Creating precise slots in various materials for mechanical components.

- Drilling Holes: Efficiently drilling holes with accurate depth and positioning.

- Cutting Sharp Edges: Perfect for producing clean, sharp edges on parts.

Advantages of 3-Axis Machining

- Cost-Effective: Generally more affordable than 4-axis and 5-axis machines, both in terms of purchase price and maintenance costs.

- Ease of Use: Simpler to program and operate, making it suitable for smaller shops and those new to CNC machining.

- Versatility: Capable of performing a wide range of basic machining operations.

Limitations of 3-Axis Machining

- Complexity Constraints: Limited to simpler geometries, as it cannot handle complex shapes and undercuts.

- Setup Time: Requires multiple setups to machine different sides of a part, increasing overall production time.

4-Axis CNC Machines

4-axis machining builds upon the capabilities of 3-axis machines by adding rotary movement around the X axis, known as the A axis. This additional axis allows the workpiece to be rotated, enabling cuts to be made on multiple sides without manual repositioning. The 4-axis method is particularly beneficial for:

- Intermittent Cutting: The ability to rotate the workpiece allows for cutting on different faces without re-clamping.

- Continuous Cutting: Ideal for complex contouring and sculpting applications.

- Engraving Curved Surfaces: Enables detailed engraving and cutting on curved surfaces.

Advantages of 4-Axis Machining

- Increased Flexibility: The additional axis allows for more complex geometries and reduces the need for multiple setups.

- Improved Precision: The ability to rotate the workpiece ensures consistent accuracy across different sides.

- Time Efficiency: Reduces the time required for repositioning the workpiece, enhancing overall production efficiency.

Limitations of 4-Axis Machining

- Complexity in Programming: Requires more advanced programming skills and software to manage the additional axis.

- Higher Costs: More expensive than 3-axis machines in terms of purchase and maintenance.

5-Axis CNC Machines

5-axis machining takes the process further by allowing the workpiece to be manipulated from five sides simultaneously. In addition to the movements along the X, Y, and Z axes, 5-axis machines can utilize two of the three rotational axes (A, B, C). This advanced capability is crucial for industries such as automotive, aerospace, and marine, where complex components are required. Benefits of 5-axis machining include:

- Feature Accuracy: Achieving high precision on intricate features and complex geometries.

- Increased Productivity: The ability to machine from five sides in a single setup drastically reduces production time.

- Higher Quality Finishes: Produces smoother surface finishes by minimizing the need for manual repositioning.

- Cutting Intricate Details: Ideal for components requiring detailed and precise machining.

- Machining Complex Shapes: Capable of handling parts with complex contours and undercuts that would be impossible with fewer axes.

Advantages of 5-Axis Machining

- Reduced Setup Time: Minimizes the need for multiple setups, significantly reducing overall production time.

- Enhanced Flexibility: Allows for the machining of more complex parts in a single setup.

- Improved Surface Quality: Reduces the need for manual finishing by producing higher quality surface finishes directly from the machine.

Limitations of 5-Axis Machining

- High Initial Investment: Significantly more expensive to purchase and maintain than 3-axis or 4-axis machines.

- Complex Programming: Requires advanced programming skills and software to manage the multiple axes.

- Operational Expertise: Necessitates highly skilled operators to fully utilize the machine’s capabilities.

Applications of CNC Machining in Different Industries

صناعة السيارات

In the automotive industry, CNC machining is used to produce a wide range of components, including engine parts, transmission components, and chassis parts. The precision and repeatability of CNC machining ensure high-quality parts that meet stringent industry standards.

صناعة الطيران والفضاء

The aerospace industry demands extremely high precision and quality due to the critical nature of its components. CNC machining is used to manufacture complex parts such as turbine blades, structural components, and intricate brackets, ensuring that they meet the rigorous standards required for aerospace applications.

Medical Industry

In the medical industry, CNC machining is used to produce medical devices, implants, and surgical instruments. The high precision and accuracy of CNC machining ensure that these critical components meet the strict requirements of the medical field.

Marine Industry

CNC machining is used in the marine industry to manufacture components such as propellers, hull fittings, and engine parts. The ability to handle complex shapes and tough materials makes CNC machining ideal for producing durable and reliable marine components.

Key Benefits of CNC Machining

CNC machining is operationally beneficial across various manufacturing-intensive industries. The primary advantages include:

- Improved Product Quality Control: Consistency in manufacturing leads to standardized, high-quality products.

- Enhanced Precision: Automated controls ensure precise cuts and shapes.

- Cost Reduction: Automation reduces labor costs and material waste.

- Speed: Faster production cycles compared to manual machining.

Axes Movements in CNC Machining

- X Axis: Left to right

- Y Axis: Front to back

- Z Axis: Up and down

- A Axis: 180° rotation around the X axis

- B Axis: 180° rotation around the Y axis

- C Axis: 180° rotation around the Z axis

Types of CNC Machines

- 3 Axis: X, Y, and Z axes

- 4 Axis: X, Y, Z, and A axes

- 5 Axis: X, Y, and Z axes plus two of A, B, and C axes

نبذة عن GCH

At GCH, we deliver business solutions that bridge the gap between strategy and execution for global organizations of all sizes. Our portfolio spans workforce management, engineering, quality lifecycle management (QLM), and information technology (IT). With robust engineering and IT expertise, we collaborate with global clients to provide CNC programming and validation services tailored to their business needs.

Learn more about our engineering services at GCH.

الخاتمة

التصنيع الآلي باستخدام الحاسب الآلي, with its varying axes and capabilities, offers unparalleled precision and efficiency in manufacturing. Whether utilizing a 3-axis, 4-axis, or 5-axis machine, manufacturers can achieve high levels of accuracy and productivity, making CNC machining an indispensable tool in modern manufacturing. The choice of machine depends on the complexity of the parts, the required precision, and the specific industry requirements. By understanding the distinct advantages and limitations of each type of CNC machine, manufacturers can optimize their production processes and achieve superior results.