Metals like stainless steel are known for their strength, durability, and corrosion resistance, making them ideal for a wide range of industrial applications. One of the most common and effective methods for shaping and finishing stainless steel is CNC machining. But what exactly is CNC machining, and why is stainless steel such a popular choice for this process?

This article will explore the ins and outs of stainless steel CNC machining, covering everything from how the process works, to its key benefits and various applications.

What Is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process in which pre-programmed computer software controls the movement of machinery and tools. This allows for highly precise and efficient shaping of metal parts. CNC machining is compatible with a wide range of materials, including metals, plastics, and composites, but stainless steel remains a top choice due to its combination of strength and machinability.

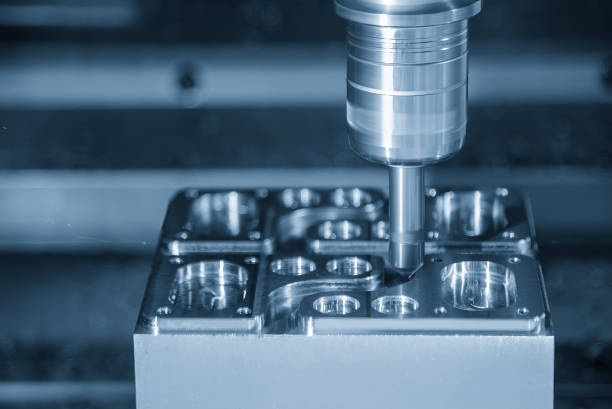

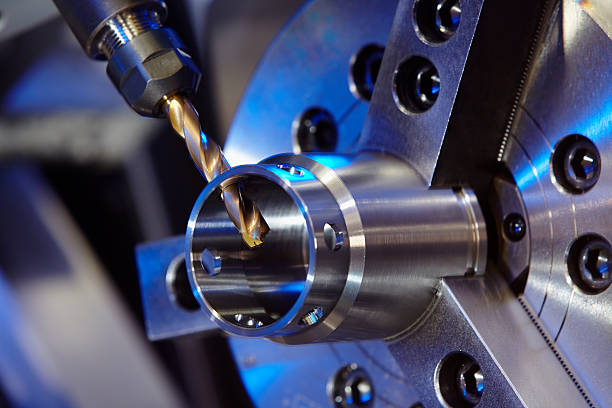

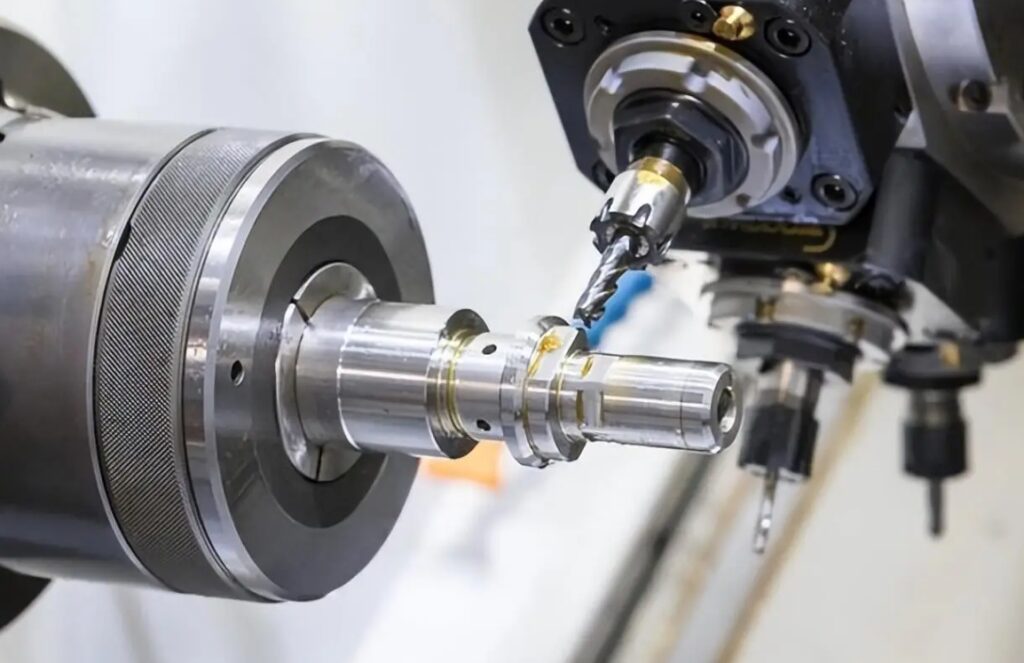

In CNC machining, various tools such as lathes, mills, and routers are used to cut, drill, and shape materials into complex designs with tight tolerances. The process starts with a CAD (Computer-Aided Design) model, which is translated into a set of instructions that guide the CNC machine.

Popular Science Knowledge About Stainless Steel :https://en.wikipedia.org/wiki/Stainless_steel

Why Choose Stainless Steel for CNC Machining?

Stainless steel stands out as a top material for CNC machining for several reasons:

- Corrosion Resistance: Stainless steel contains chromium, which forms a thin layer of oxide on the surface that prevents rust and corrosion. This makes it ideal for parts exposed to harsh environments.

- Strength and Durability: Stainless steel is known for its excellent mechanical properties, including high tensile strength and durability. This ensures that machined parts can withstand heavy loads and long-term use.

- Aesthetic Appeal: Stainless steel has a naturally shiny and smooth surface, which adds a sleek, professional appearance to any component.

- Temperature Resistance: Stainless steel can withstand high temperatures, making it suitable for applications involving extreme heat.

Types of Stainless Steel Used in CNC Machining

There are several grades of stainless steel commonly used in CNC machining, each with its own specific properties:

- 304 Stainless Steel: Known for its corrosion resistance and strength, 304 stainless steel is one of the most commonly used grades in various industries, including food processing and chemical equipment.

- 316 Stainless Steel: Contains molybdenum, which enhances corrosion resistance in saline or marine environments. It’s commonly used in marine applications and medical devices.

- 410 Stainless Steel: A martensitic grade that offers high strength and wear resistance, making it ideal for applications where durability is key.

- 17-4 PH Stainless Steel: A precipitation-hardened stainless steel that combines high strength with excellent corrosion resistance, used in aerospace and chemical processing industries.

The CNC Machining Process for Stainless Steel

Stainless steel CNC machining typically involves several steps:

- Design and Programming: A CAD model of the part is created and converted into a CNC program. This program dictates the precise movements of the CNC machine.

- Material Preparation: A stainless steel block or rod is selected and secured in the machine. The choice of stainless steel grade depends on the specific application.

- Machining Operations: Depending on the design, the CNC machine may perform various operations such as milling, turning, drilling, and grinding. The high precision of CNC machining ensures that even complex shapes can be achieved with tight tolerances.

- Finishing: After the machining is complete, the part may undergo finishing operations such as deburring, polishing, or passivation. These processes enhance the appearance and performance of the machined part.

- Quality Control: Finally, the machined part is inspected for accuracy and consistency using measuring tools such as calipers and coordinate measuring machines (CMM).

Benefits of Stainless Steel CNC Machining

Stainless steel CNC machining offers a range of benefits:

- Precision and Accuracy: CNC machining allows for tight tolerances and precise measurements, ensuring that parts meet exact specifications.

- Efficiency: Once programmed, CNC machines can operate continuously, producing large quantities of parts with minimal human intervention.

- Customizability: The CNC process allows for easy customization of parts, whether for small-batch production or large-scale manufacturing.

- Reduced Waste: CNC machining is highly efficient in material use, minimizing waste compared to traditional manufacturing methods.

Common Applications of Stainless Steel CNC Machining

Thanks to its versatility, stainless steel CNC machining is used across a wide range of industries. Some common applications include:

- Aerospace Components: Stainless steel’s strength and corrosion resistance make it ideal for aerospace parts that must withstand extreme conditions.

- Medical Devices: Stainless steel is used for surgical tools, implants, and other medical devices due to its biocompatibility and ability to be sterilized.

- Automotive Parts: Stainless steel components, such as engine parts and exhaust systems, benefit from the material’s durability and heat resistance.

- Food and Beverage Equipment: The corrosion resistance of stainless steel makes it perfect for food processing equipment, which must meet strict hygiene standards.

- Marine Applications: In salty or wet environments, such as marine hardware, stainless steel parts resist corrosion and maintain their structural integrity.

Alternatives to CNC Machining Stainless Steel

While CNC machining is highly effective for stainless steel, other manufacturing methods may be more appropriate depending on the application:

- Laser Cutting: For thin stainless steel sheets, laser cutting provides a fast and precise alternative.

- Water Jet Cutting: Water jet cutting uses high-pressure water to cut stainless steel, offering a heat-free alternative to CNC machining.

- 3D Printing: Stainless steel 3D printing is becoming more common for custom, low-volume parts that don’t require the precision of CNC machining.

Conclusion

Stainless steel CNC machining is a highly efficient and precise method for producing parts with exceptional strength, durability, and corrosion resistance. While the process can be more challenging than machining other metals, the benefits far outweigh the difficulties, particularly in industries that require long-lasting and high-performance components.

Whether you’re working in aerospace, medical devices, automotive, or another demanding industry, stainless steel CNC machining provides the versatility and precision you need to meet the most exacting standards.

FAQs

What are the advantages of using stainless steel in CNC machining?

Stainless steel offers excellent corrosion resistance, strength, durability, and heat resistance, making it a top choice for high-performance parts in demanding environments.

Can stainless steel be difficult to machine?

Yes, due to its hardness and toughness, stainless steel can be more challenging to machine compared to softer metals like aluminum. However, with the right tools and settings, CNC machines can handle stainless steel efficiently.

Is CNC machining the best method for producing stainless steel parts?

For high-precision parts, CNC machining is an excellent choice. However, for some applications, other methods like laser cutting or water jet cutting may be more appropriate.