As the world transitions toward a more sustainable future, the renewable energy sector is experiencing rapid growth and innovation. CNC machining services play a crucial role in this transition, providing the precision and reliability needed to produce components for wind turbines, solar panels, and other renewable energy technologies. This article explores how CNC machining services are contributing to the renewable energy sector, the challenges involved, and the future of machining in sustainable energy.

The Role of CNC Machining in Renewable Energy

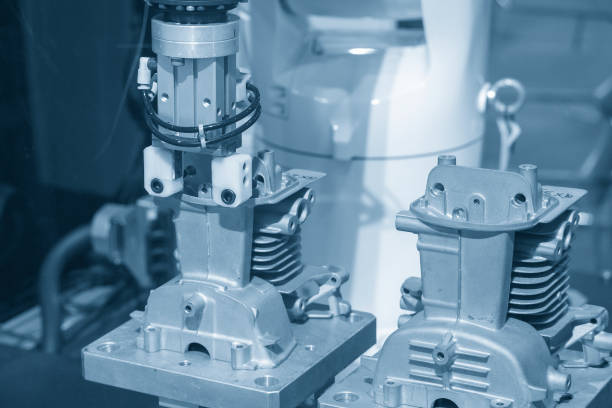

CNC machining services are essential in the production of components for renewable energy systems. These systems require high precision and durability to operate efficiently and withstand harsh environmental conditions. Key applications of CNC machining in the renewable energy sector include:

Wind Turbines: Wind turbines are complex systems that require precise machining of components such as rotor hubs, gearbox housings, and generator parts. CNC machining services ensure that these components meet the tight tolerances and high strength requirements needed for reliable operation.

Solar Panels: The production of solar panels involves the machining of components such as frames, mounting systems, and electrical connectors. CNC machining services provide the accuracy and consistency needed to produce these components with high efficiency.

Hydroelectric Power: Hydroelectric power systems rely on turbines, generators, and other components that require precise machining. CNC machining services produce these parts to exact specifications, ensuring optimal performance and longevity.

Energy Storage: Energy storage systems, such as batteries and capacitors, require precise machining of enclosures, connectors, and thermal management components. CNC machining services ensure that these components meet the necessary safety and performance standards.

Challenges in CNC Machining for Renewable Energy

The renewable energy sector presents unique challenges that CNC machining services must address to meet the industry’s demands:

Material Durability: Renewable energy systems often operate in harsh environments, such as offshore wind farms or desert solar installations. Components must be made from durable materials that can withstand these conditions. CNC machining services must be capable of working with advanced materials, such as corrosion-resistant alloys and composites, to produce long-lasting components.

Large-Scale Machining: Many renewable energy components, such as wind turbine blades and hydroelectric turbine parts, are large and require specialized CNC machining equipment. The scale of these components presents challenges in terms of machining accuracy, setup, and handling.

Precision and Efficiency: Renewable energy systems must operate with high efficiency to be economically viable. CNC machining services must produce components with tight tolerances and high precision to ensure that these systems perform optimally.

Sustainability: The renewable energy sector is inherently focused on sustainability, and CNC machining services must align with these goals. This includes minimizing material waste, reducing energy consumption, and using environmentally friendly processes.

CNC Machining Techniques for Renewable Energy

To meet the challenges of the renewable energy sector, CNC machining services employ a range of advanced techniques:

High-Precision Milling: High-precision milling is used to machine components with tight tolerances, such as gearboxes and generator parts for wind turbines. This technique ensures that components fit together perfectly and operate with minimal friction and wear.

Multi-Axis Machining: Multi-axis CNC machines, such as 5-axis machines, are used to machine complex geometries in a single setup. This capability is essential for producing intricate components, such as turbine blades and solar panel mounts, with high precision.

Electrochemical Machining (ECM): Electrochemical machining is a non-contact process that uses electrical energy to remove material. ECM is ideal for machining hard materials and creating complex shapes without inducing stress or heat in the workpiece.

Cryogenic Machining: Cryogenic machining involves using liquid nitrogen to cool the cutting tool and workpiece during machining. This technique reduces tool wear and improves precision when machining difficult-to-cut materials, such as titanium and superalloys used in renewable energy components.

The Future of CNC Machining in Renewable Energy

As the renewable energy sector continues to grow, CNC machining services will play an increasingly important role in meeting new challenges and demands. Key trends shaping the future of CNC machining in renewable energy include:

Additive Manufacturing Integration: The integration of CNC machining with additive manufacturing (3D printing) is expected to play a significant role in renewable energy. This hybrid approach allows for the production of complex components with reduced material waste and improved design flexibility.

Automation and Robotics: The use of automation and robotics in CNC machining is increasing efficiency and reducing production times in renewable energy manufacturing. This trend will continue as manufacturers seek to optimize their production processes and meet the growing demand for renewable energy components.

Advanced Materials: The development of new, advanced materials will drive the need for CNC machining services capable of working with these materials. This includes the use of high-performance alloys, composites, and ceramics in renewable energy applications.

Sustainability Initiatives: The renewable energy sector is inherently focused on sustainability, and CNC machining services must align with these goals. This includes minimizing material waste, reducing energy consumption, and using environmentally friendly processes.

Conclusion

CNC machining services are playing a crucial role in powering the renewable energy sector, providing the precision and reliability needed to produce components for wind turbines, solar panels, and other sustainable energy technologies. By overcoming the challenges of material durability, large-scale machining, and sustainability, CNC machining services ensure that renewable energy systems operate efficiently and reliably.

As the renewable energy sector continues to grow, CNC machining services will play an increasingly important role in meeting new challenges and demands. By embracing advanced techniques, integrating with additive manufacturing, and focusing on sustainability, CNC machining services will continue to support the transition toward a more sustainable future.