Since the dawn of the automotive industry in the 1860s, it has consistently evolved through innovation and technological advancements. Many of the most significant strides in the automotive sector are directly linked to improvements in manufacturing processes. CNC (Computer Numerical Control) machining plays a pivotal role in these advancements, driving the industry forward.

In 1913, Henry Ford revolutionized car manufacturing with the introduction of the moving assembly line, making mass-produced vehicles accessible worldwide. Precision in auto parts production and efficient manufacturing processes have been critical goals since then.

In recent years, advancements in design, robotics, and manufacturing have led to significant automation in automotive machining. These technologies have also enhanced vehicle design and performance. CNC machining, in particular, has been instrumental in transforming car manufacturing.

Benefits of CNC Machining in Automotive Applications

CNC machining has gained immense popularity in the automotive industry due to its numerous benefits. Manufacturers worldwide leverage this technology to gain advantages such as speed, automation, repeatability, and precision. Here are some key benefits of CNC machining for automotive applications:

Speed

CNC machining offers rapid production times for medium to high-volume manufacturing compared to traditional methods. Its automated nature reduces the need for labor-intensive manual operations, accelerating the production process.

Automation

Automation is a standout advantage of CNC machining. It enables faster production cycles and streamlines the automotive manufacturing process. For example, robotic arms can assist in removing parts once completed, allowing workers to focus on design and innovation tasks.

Repeatability

CNC machining ensures high repeatability, essential for industrial-grade production. Consistency in parts production is crucial in the automotive industry to maintain high standards, ensuring that all components meet the same quality criteria.

Precision

CNC machining can achieve tight tolerances necessary for critical automotive components like engine parts and other functional elements. The process guarantees precise auto parts and can handle complex geometries with ease.

Customization

While CNC machining may not be as suited for customization as additive manufacturing, it can still produce customized automotive parts with short lead times, whether for one-off items or small production runs.

Prototyping Applications of CNC Machining in the Automotive Industry

CNC machining is invaluable for both prototyping and production in the automotive sector. It excels in creating high-quality, functional prototypes that undergo rigorous testing and validation before mass production. The process is suitable for various vehicle parts, including metal and plastic components, and can showcase intricate design features for car interiors.

For instance, CNC machining can quickly produce clear acrylic prototypes for lighting components or high-quality functional prototypes for performance testing in new car models.

Production Applications of CNC Machining in the Automotive Industry

Beyond prototyping, CNC machining is crucial for manufacturing numerous automotive parts, including:

Interior Panels

CNC machining can produce interior vehicle components like dashboard panels with the precision needed for aligning cutouts for instruments such as the speedometer and gas gauge.

Starter Motors

Complex parts like starter motors benefit from CNC machining’s precision and complexity. The process allows for optimizing these components for better performance, durability, and reliability.

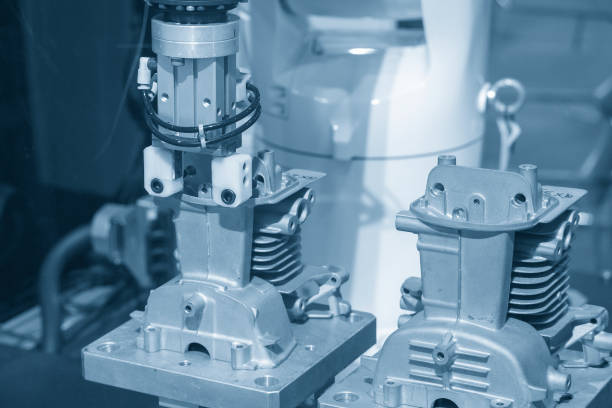

Cylinder Heads

CNC machining is advantageous for producing engine blocks and cylinder heads, essential for internal combustion engines. This technology is especially useful for limited production runs or customized engine models, typically machined from solid blocks of aluminum.

Drive Axles

CNC machining produces precision components for the drive axle mechanism, such as hypoid gears and bevel gears, enabling smooth vertical movement and pivoting during turns.

Gearboxes

The gearbox, a critical part of a vehicle’s transmission system, consists of various shaft and gear components that CNC machining can produce with high precision and efficiency.

Custom Parts

OEMs use CNC machining to produce customized components or rare replacement parts. In vintage car restoration, CNC machining, combined with reverse engineering, creates unique parts that might otherwise be obsolete.

CNC Machining vs. 3D Printing for Automotive Applications

The automotive industry employs various digital manufacturing technologies, including CNC machining and 3D printing. CNC machining is a subtractive process that removes material from a solid workpiece, while 3D printing is an additive process that builds parts layer by layer.

Interior panels can be produced using either method. CNC machined panels are durable and made from a wide range of materials, whereas 3D printed panels are ideal for rapid prototyping. Each method has its unique benefits, with CNC machining favored for its robustness and reliability, and 3D printing for its speed and customization capabilities.

GCH Process CNC Machining Services

At GCH Process, we offer comprehensive CNC machining capabilities, including three, four, and five-axis machining. Our services encompass a broad range of materials, such as aluminum alloys, steel, titanium, and plastics. Leveraging our expertise and extensive manufacturing network, we deliver automotive components swiftly and accurately.

We cater to various production needs, from single-run prototypes to large volume manufacturing. Understanding the high standards of the automotive industry, we prioritize precision and quality control in every car part we produce.

For critical components, we accommodate fine tolerances down to +/-0.01 mm, ensuring the creation of complex interlocking systems with a tight fit. We guarantee quality through rigorous quality control techniques, including technical assessments, material verification, on-machine inspection probes, in-process quality control, and first-article inspection. Full-dimensional inspection reports are available upon request, all at competitive prices.

Conclusion

CNC machining, with its varying axes and capabilities, offers unparalleled precision and efficiency in automotive manufacturing. Whether utilizing a 3-axis, 4-axis, or 5-axis machine, manufacturers can achieve high levels of accuracy and productivity, making CNC machining an indispensable tool in the automotive industry. The choice of machine depends on the complexity of the parts, required precision, and specific industry requirements. By understanding the distinct advantages and limitations of each type of CNC machine, manufacturers can optimize their production processes and achieve superior results.

FAQ

What products are made by CNC machining for the automotive industry?

CNC machined prototypes in the automotive industry can include anything from headlight covers to engines. CNC machining also produces end-use car parts, such as cylinder heads, starter motors, gearboxes, and custom components for rare and vintage cars.

What kind of CNC machine is used in the automotive industry?

Simple or one-sided car parts can be made using various CNC machines. However, complex items like cylinder heads and blocks typically require expensive 5-axis machining centers, which offer a wider range of cutting tool angles and enable the creation of highly complex geometries with tight tolerances.

What materials are used in automotive CNC machining?

Different parts require different materials, including metals and plastics. For instance, manufacturing cylinder blocks and heads often involves aluminum, known for its excellent heat dissipation properties.

By expanding the discussion on CNC machining for the automotive industry and including detailed insights into applications, advantages, and comparisons with other technologies, this comprehensive guide provides a well-rounded perspective for readers.