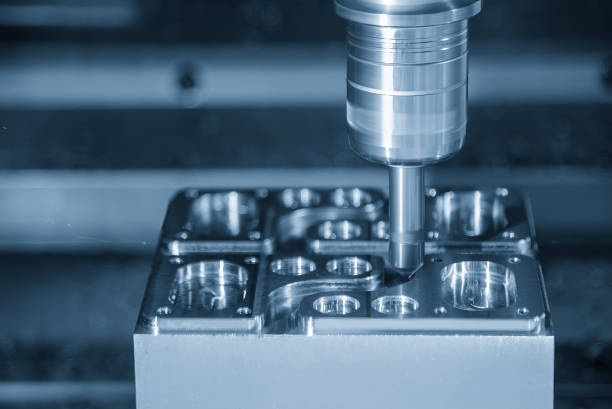

In the world of manufacturing, CNC (Computer Numerical Control) machines are invaluable tools that streamline the production of custom parts. While many enthusiasts have small CNC machines in their garages, for larger and more intricate projects, turning to professional services like GCH is often necessary. In this article, we’ll explore the factors influencing CNC milling costs and what you should consider for your next project.

Key Factors Influencing CNC Milling Costs

1. Machine Size: The size of the CNC machine significantly impacts its cost. A small desktop CNC mill is far less expensive than a larger mill with a 5’x5’x5’ work envelope. Larger machines demand more materials and components, which increases manufacturing complexity and cost. The size of the parts you need will dictate the size of the machine required.

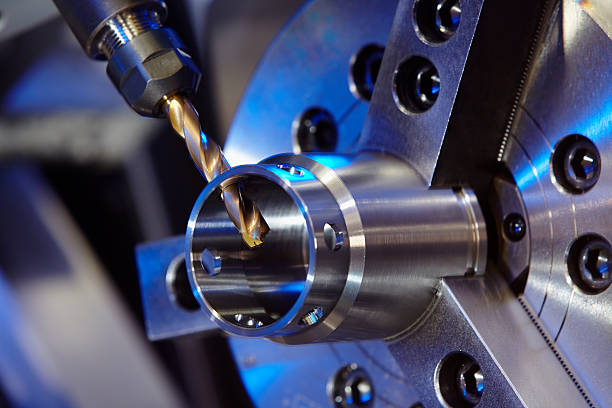

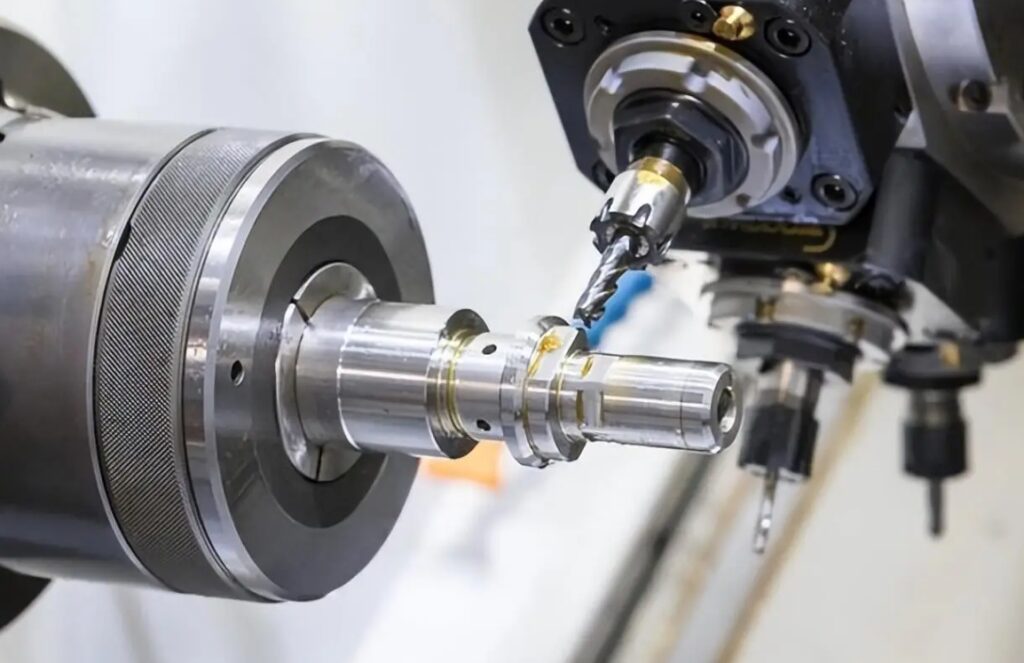

2. Machine Complexity: Advanced CNC machines with features like multiple axes of motion and automation capabilities are more expensive. A machine with a 20-position automatic tool changer, for instance, offers tremendous convenience but adds to the overall cost.

3. Machine Accuracy: Machines offering high precision and accuracy come at a premium. While a hobby CNC machine might provide accuracy to +/- 0.010”, industrial machines with tolerances of +/- 0.0003” or better can cost significantly more, often justified by the demands of precision engineering.

4. Machine Speed: Higher-speed CNC machines, equipped with powerful motors and robust control systems, are more costly. Despite the higher initial investment, these machines often boost productivity, potentially offsetting the additional cost over time.

5. Material Compatibility: Machines capable of working with a diverse range of materials—metals, plastics, woods—are generally more expensive than those limited to specific materials.

6. Brand and Reputation: Reputable brands command higher prices due to their proven reliability and support. Investing in a well-known brand can offer peace of mind and often better resale value.

7. Additional Features: Optional extras like automatic tool changers, coolant systems, and specialized software can increase the cost. These features, while adding to the expense, often enhance efficiency and precision.

Types of CNC Machines and Their Costs

Different CNC machines come with varying costs based on their functionality and application:

- Entry-Level Desktop CNC Routers: $150 – $500

- Hobby-Level CNC Routers: $1,000 – $3,000

- Hobby-Level CO2 Lasers: $1,000 – $3,000

- Small Business Plasma Tables: $1,000 – $5,000

- Professional CNC Machines: $50,000 – $100,000

- Entry-Level 3-axis Mills: $50,000 – $100,000

- Industrial HD Plasma Tables: $40,000 – $120,000

- Industrial Fiber Lasers: $100,000 – over $500,000

- Production 3-axis CNC Milling Machines: $100,000 – $500,000

- Production 5-axis CNC Milling Machines: Over $500,000

These machines’ prices reflect factors like size, power, cutting speed, precision, and additional features.

Additional Costs in CNC Milling

Beyond the machine itself, several other costs should be considered:

- Tools and Accessories: These may include lubricants, coolants, twist drills, milling vises, and measuring tools.

- Staffing and Training: Operators’ salaries and training costs should be factored in.

- Maintenance and Repairs: Regular maintenance is crucial for machine longevity and performance.

- Software: Ensuring compatibility with existing systems and the cost of necessary software licenses.

Should You Buy or Outsource?

For many small businesses, outsourcing CNC milling to a specialized provider like GCH can be more economical than purchasing a machine. Outsourcing eliminates the need for significant capital investment and ongoing maintenance. GCH offers a range of CNC milling services with capabilities that can handle complex and high-volume projects efficiently.

Buying Used CNC Machines

Purchasing used CNC machines can be a cost-effective alternative, especially for machines over $10,000. Sites like MachineTools offer a marketplace for buying and selling used machinery. When buying used, thorough inspections and evaluations are essential to ensure you’re making a sound investment.

Conclusion

Understanding the costs associated with CNC milling is crucial for making informed decisions. By considering machine size, complexity, accuracy, speed, material compatibility, brand reputation, and additional features, you can better gauge the investment required. Whether you decide to purchase a CNC machine or outsource to a professional service like GCH, evaluating these factors will help you achieve the best results for your manufacturing needs.

For further assistance with your CNC milling projects, visit GCH’s website to learn more about our services and get an instant quote.