Your Premier Customization Partner in Aerospace

صناعة الطيران والفضاء

GCH Precision Prototyping and On-Demand Production Pioneering Solutions for the Aerospace Industry

- Superior craftsmanship in aerospace components

- حاصلة على شهادة الأيزو 9001:2015

- دعم هندسي على مدار 24/7

- الصفحة الرئيسية

- صناعة الطيران والفضاء

لماذا تختارنا

At GCH, we transcend traditional manufacturing. We are the vanguard of innovation for the aerospace industry, with a team of experts harnessing state-of-the-art technology. Our bespoke strategies and meticulous craftsmanship ensure that every aerospace project is executed with precision and excellence.

البراعة التقنية

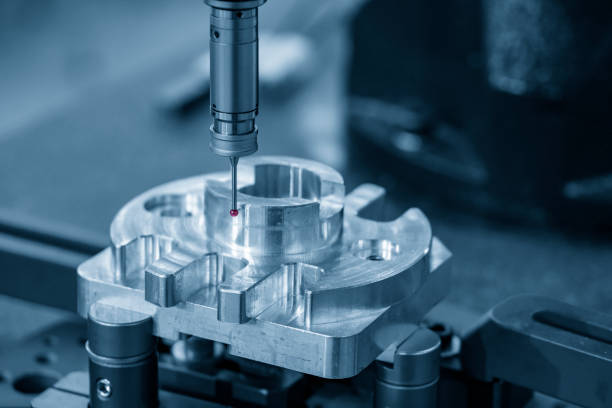

Our ISO 9001:2015 certification is a seal of our commitment to excellence. We fabricate aerospace components using the most suitable materials and cutting-edge techniques, including CNC machining, laser cutting, and additive manufacturing.

عروض الخدمات المخصصة حسب الطلب

Whether for rapid prototyping to validate design concepts or for scaled manufacturing to meet market demands, GCH provides fully tailored services. Our mission is to transform your aerospace aspirations into tangible realities.

تصنيع المكونات الدقيقة

We comprehend the exacting standards of the aerospace sector for precision parts. Our manufacturing capabilities are engineered to satisfy the most stringent tolerance specifications, guaranteeing the seamless operation and superior performance of your aerospace components.

ضمان الجودة والتحسين المستمر

Our pursuit of quality is unrelenting. Through rigorous quality control measures and the deployment of advanced inspection technologies, we ensure that your products not only conform to standards but also surpass expectations.

موثوق بها من قبل شركات فورتشن 500

Our roster of partners includes esteemed aerospace manufacturers who place their trust in our innovative solutions and dependability. We foster intimate collaborations with our clients to deliver personalized solutions for every aerospace project.

- Aerospace system developers

- Innovators in satellite technology

- Pioneers in space exploration

- Research and educational institutions in aerospace engineering Pioneers in space exploration

- Suppliers of aircraft components and assemblies

- Experts in aerodynamic testing and simulation

Manufacturing Capabilities for Aerospace Components

Our rapid prototyping and on-demand production services are crafted for businesses aiming to lead in the dynamic aerospace market. Our comprehensive capabilities encompass material science proficiency, exacting process control, high-caliber production, and a robust quality management system.

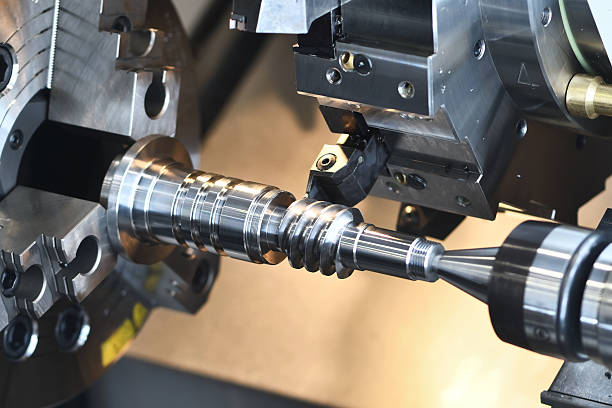

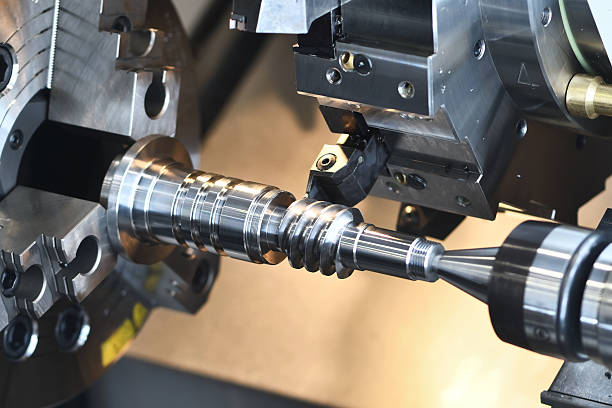

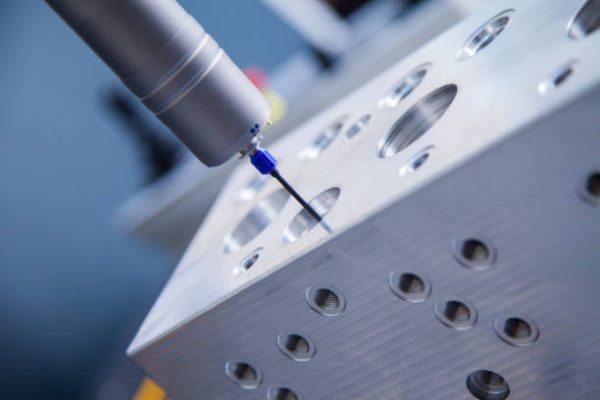

التصنيع الآلي باستخدام الحاسب الآلي

التصنيع الآلي السريع والدقيق باستخدام ماكينات بنظام التحكم الرقمي من خلال استخدام أحدث المعدات والمخارط ثلاثية المحاور وخماسية المحاور.

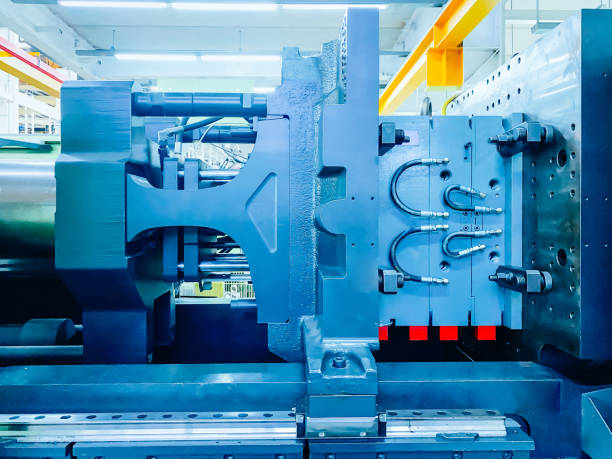

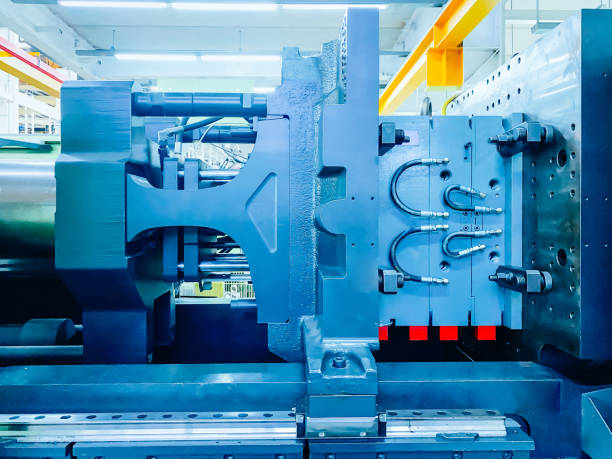

الصب بالقالب

Custom Die Casting service for the manufacturing of competitive pricing, high-quality plastic prototyping and production parts in a fast lead time.

الصب بالليزر

تضمن لنا خبرتنا في مجال الصب بالتفريغ سرعة إنتاج النماذج الأولية للأجزاء البلاستيكية المصنوعة من البلاستيك المرن ذات التصميمات المعقدة والمفصلة للغاية.

Materials for Aerospace Components

اعتمادًا على متطلبات قطع الطيران الخاصة بك، تتوافق عمليات التصنيع الآلي لدينا مع مجموعة كبيرة من المواد. لدينا قائمة طويلة من المواد المعدنية والمركبة من فئة الإنتاج التي تلبي متطلبات صناعة الطيران. اطلع على بعض المواد شائعة الاستخدام لمكونات صناعة الطيران.

ألومنيوم

يتميز الألومنيوم بنسبة قوة إلى وزن ممتازة لهذا المعدن. وهو خيار رائع لمتطلبات التحميل العالية لأقواس ومبيتات الطائرات. يتميز الألومنيوم أيضاً بليونة جيدة، وصلابة، ومقاومة للتآكل، وقابلية التشغيل الآلي. كما أن خواصه خفيفة الوزن تجعله مفيداً للتطبيقات الهيكلية للطائرات مثل جلد جسم الطائرة، وأوتار الأجنحة، وجلود الأجنحة، وما إلى ذلك.

السعر: $

المهلة الزمنية: < أقل من 10 أيام

التفاوتات المسموح بها: ± 0.125 مم (± 0.005 ″)

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

تيتانيوم

يتميّز التيتانيوم بعدد من الخصائص المادية التي تجعله المعدن المثالي للتطبيقات الصعبة. وتشمل هذه الخصائص مقاومة ممتازة للتآكل والمواد الكيميائية ودرجات الحرارة القصوى. كما يتمتع المعدن بنسبة قوة إلى وزن ممتازة.

تجعل هذه الخصائص من سبائك التيتانيوم خيارات رائعة لهياكل الطائرات ومحركات الطائرات.

السعر: $$$

المهلة الزمنية: < أقل من 10 أيام

سُمك الجدار: 0.75 مم

التفاوتات المسموح بها: ± 0.125 مم (± 0.005 ″)

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

الفولاذ المقاوم للصدأ

الصلب هو معدن آخر يستخدم في إنتاج قطع غيار السيارات الحديثة. هذا المعدن متين وفعال في الأداء. كما أنه يسهل إنتاج أجزاء عالية الجودة. كما أنه مقاوم للتآكل وخفيف الوزن ويؤدي إلى إنتاج أجزاء مبهجة من الناحية الجمالية. يستخدم هذا المعدن في إنتاج مكابح السيارات، والمحركات، وأنظمة العادم، والعجلات، وغيرها.

السعر: $

المهلة الزمنية: < أقل من 10 أيام

سُمك الجدار: 0.75 مم

التفاوتات المسموح بها: ± 0.125 مم (± 0.005 ″)

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

النحاس

يلعب النحاس دوراً كبيراً في الراحة والكفاءة والسلامة في صناعة السيارات. إنه موصل ممتاز للكهرباء ومطاطي للغاية وقابل للطرق. وله استخدامات في معظم المكونات الإلكترونية للسيارة، بما في ذلك الأسلاك الخاصة بالسيارة، والمبرد، ومحرك بدء التشغيل، ومولد الكهرباء، ومولد التيار المتردد، وأنابيب المكابح.

السعر: $

المهلة الزمنية: <أقل من 10 أيام

التفاوتات المسموح بها: ± 0.125 مم

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

المغنيسيوم

يتميز المغنيسيوم بخفة وزنه وقابليته الممتازة للصب وقوته النوعية العالية، مما يتيح له استخدامات في صناعة السيارات. ويستخدم المغنيسيوم في إنتاج كتل المحركات، وعلب التروس، وعلب التروس، وعلب القابض، والعجلات، وحوامل المحركات، وأحواض الزيت.

السعر: $

المهلة الزمنية: <أقل من 10 أيام

التفاوتات المسموح بها: ± 0.125 مم

الحد الأقصى لحجم القطعة: 200 × 80 × 100 سم

اللدائن الحرارية

تتميز هذه اللدائن الحرارية بخصائص ممتازة تتراوح بين مقاومة الصدمات العالية والقدرة على مقاومة درجات الحرارة العالية. PPS. على سبيل المثال، تتمتع بثبات أبعاد ممتاز، وتحمل درجات الحرارة ومقاومة الصلابة. يمكنك العثور على اللدائن الحرارية في الأجزاء الداخلية للمركبات، بالإضافة إلى إطارات البطاريات ومصدات المركبات.

Finishing Options for Aerospace Industry

Improve the surface quality of your plastic injection molded parts with superior surface finishing options. GCH provides an extensive list of surface treatments to improve the aesthetic appeal of your products. These efficient secondary operations also improve the mechanical qualities of prototypes and production parts.

| الاسم | المواد | اللون | الملمس | السُمك | |

| الطلاء بأكسيد الألومنيوم | ألومنيوم | شفاف، وأسود، ورمادي، وأحمر، وأزرق، وذهبي. | لمسة نهائية ناعمة وغير لامعة. | طبقة رقيقة 5-20 ميكرومتر طبقة أكسيد الأنوديك الصلبة: 60-200 ميكرومتر |

| تفجير البيد | ABS، والألومنيوم، والنحاس، والفولاذ المقاوم للصدأ، والفولاذ | غير متاح | ماتي | 0.3 مم - 6 مم |

| طلاء المسحوق | ألومنيوم، ستانلس ستيل، فولاذ مقاوم للصدأ، فولاذ | أسود، أي كود RAL أو رقم بانتون | لامع أو شبه لامع | 5052 ألومنيوم 5052 0.063″-0.500" 6061 ألومنيوم 6061 0.063″ -0.500" ألومنيوم 7075 ألومنيوم 0.125″ -0.250″ فولاذ طري 0.048″-0.500" 4130 فولاذ كرومولي 4130 0.050″-0.250" فولاذ مقاوم للصدأ 0.048″-0.500" |

| الطلاء الكهربائي | ألومنيوم، فولاذ، فولاذ مقاوم للصدأ | غير متاح | لمسة نهائية لامعة وناعمة | 30-500 ميكروغرام |

| التلميع | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | غير متاح | لامع | غير متاح |

| التنظيف بالفرشاة | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | متفاوتة | ساتان | غير متاح |

| الطباعة بالشاشة الحريرية | ألومنيوم، نحاس، فولاذ مقاوم للصدأ، فولاذ، فولاذ | متفاوتة | غير متاح | < 1 ميكرومتر |

| التخميل | الفولاذ المقاوم للصدأ | لا يوجد | لم يتغير | 5 ميكرومتر - 25 ميكرومتر |

التطبيقات

GCH’s aerospace components excel in a vast array of applications, demonstrating exceptional performance and resilience, including aircraft structures, satellite subsystems, space probes, aerodynamic test models, and advanced control systems.

- فوهات الوقود

- المبادلات الحرارية

- التركيبات المخصصة

- مقاييس فحص الملاءمة

- مكونات تدفق الغاز والسائل

- المضخات التوربينية والمشعبات

Custom Prototypes and Parts for the Aerospace Industry

Our veteran team commands unparalleled expertise in the manufacturing of custom prototypes and parts for the aerospace industry. From design to delivery, we are committed to meeting the most exacting standards.