Embarking on the Journey of Precision Machining: GCH Process Unveils the Mysteries of CNC Machining Technology

In the modern manufacturing industry, precision machining technology plays a pivotal role, and CNC machining technology, as a standout among them, is widely applied across various sectors due to its high precision, efficiency, and flexibility.

GCH Process, a company dedicated to CNC machining, is deeply rooted in the field of precision machining, offering high-quality, efficient customized machining services to our clients. Equipped with advanced CNC machining equipment and a team of experienced professionals, we are committed to providing the best machining solutions to meet the strict demands for accuracy, efficiency, and quality.

CNC Machining Technology: A New Era in Precision Manufacturing

CNC machining, or Computer Numerical Control machining, is a technology that utilizes computers to control machine tools for automated processing. With pre-programmed instructions, CNC machines can automatically process according to design drawings, achieving high precision and efficiency while minimizing human error.

The advantages of CNC machining technology are mainly reflected in the following aspects:

High Precision

CNC machining can achieve extreme precision, meeting strict requirements for part dimensions, shapes, and surface finish. Its precision far exceeds traditional manual processing methods, effectively reducing product defect rates and enhancing product quality.

High Efficiency

With a high degree of automation, CNC machining can increase production efficiency and shorten processing cycles. Compared to traditional processing methods, CNC machining can save a significant amount of labor costs and improve production benefits.

Material Diversity

CNC machining can be applied to a variety of materials, including metals, plastics, and wood, meeting the needs of different application scenarios. Whether it’s precision mechanical parts, medical devices, aerospace components, or molds and cutting tools, CNC machining is up to the task.

High Flexibility

CNC machining can be adjusted according to different design requirements, achieving a variety of complex shapes and geometric structures, meeting the customized needs for special parts.

Reproducibility

CNC machining can achieve automation and standardization of the processing process, ensuring consistent quality in each machining, meeting the needs of mass production.

GCH Process: Your Precision Machining Partner

As a professional CNC machining company, GCH Process boasts advanced machining equipment, an experienced team, and a comprehensive management system, dedicated to providing high-quality, efficient, and reliable CNC machining services.

Our Advantages

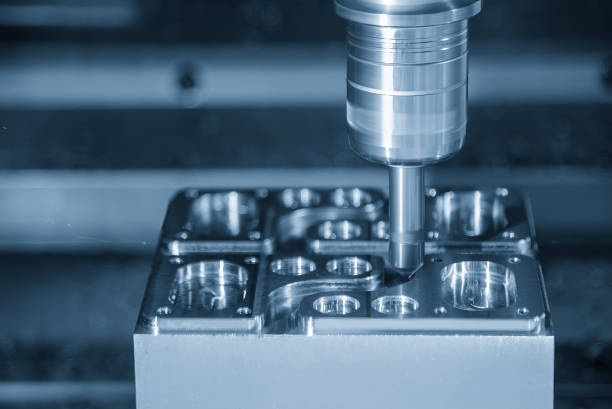

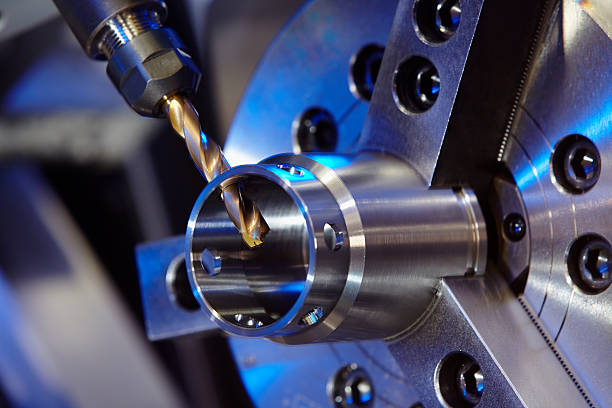

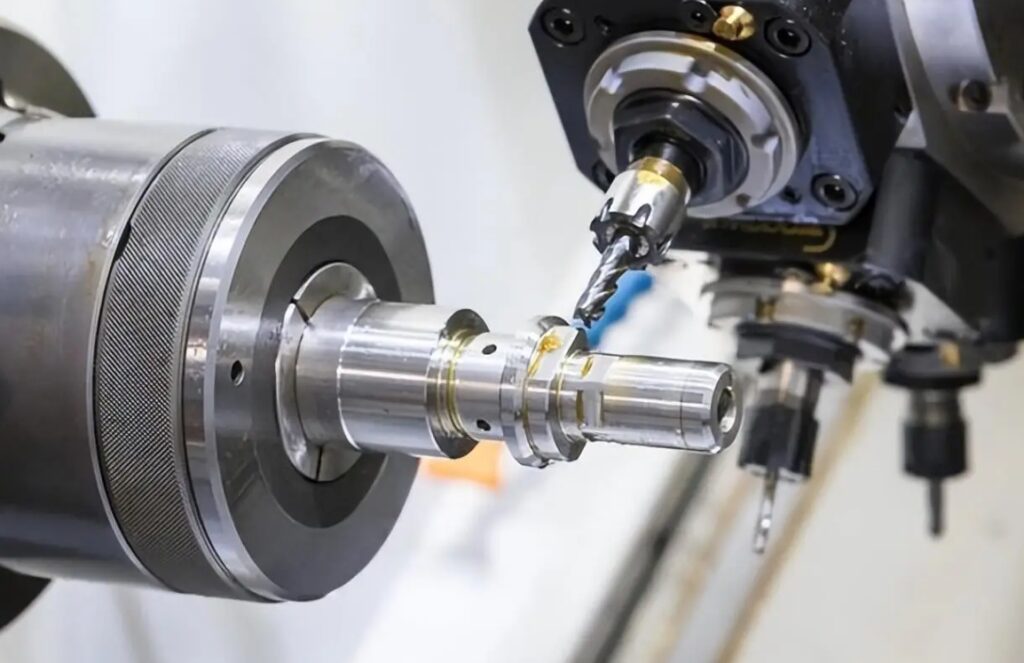

- Advanced Equipment: We possess multiple advanced CNC machines, including CNC lathes, CNC milling machines, and CNC machining centers, capable of meeting various machining needs.

- Professional Team: We have a team of experienced professionals, including senior CNC machining engineers, technicians, and quality control personnel, ready to provide professional technical support and services.

- Comprehensive Management System: We have established a comprehensive quality management system, strictly controlling every machining link to ensure processing quality and delivery time.

- Customized Services: We can provide customized machining solutions based on different client needs, satisfying their personalized requirements.

- Efficient Communication: We focus on communication with clients, promptly understanding their needs and providing timely technical support and services.

GCH Process’s CNC Machining Services

- Mechanical Part Machining: A variety of precision mechanical parts, including bearings, gears, screws, springs, etc.

- Mold Machining: Various molds, including injection molds, stamping molds, die-casting molds, etc.

- Medical Device Machining: Various medical devices, including surgical instruments, medical device components, etc.

- Aerospace Component Machining: Various aerospace components, including aircraft engine parts, rocket components, etc.

- Other Machining Services: Providing other customized machining services based on client needs.

CNC Machining Application Fields

CNC machining technology is widely applied across various industries, such as:

- Automotive Manufacturing: Automotive component machining, automotive mold design, etc.

- Aerospace: Aircraft engine parts, rocket components, etc.

- Medical Devices: Surgical instruments, medical device components, etc.

- Electronic Products: Components for mobile phones, computers, tablets, etc.

- Mold Manufacturing: Injection molds, stamping molds, die-casting molds, etc.

- Mechanical Machining: Various precision mechanical part machining.

- Tool Manufacturing: Various tools, cutting tools, etc.

Future Outlook

As technology continues to advance, CNC machining technology will keep evolving, with an even broader range of applications. In the future, technologies like artificial intelligence, big data, and cloud computing will deeply integrate with CNC machining technology, achieving higher precision, efficiency, and flexibility in machining, bringing new transformations to the manufacturing industry.

Choose GCH Process to Begin a New Chapter in Precision Machining

If you are looking for a reliable CNC machining partner, GCH Process is your top choice. We have advanced equipment, a professional team, and a comprehensive management system, capable of providing high-quality, efficient, and cost-effective CNC machining services to meet all your machining needs.