Hey there, manufacturing enthusiasts! Ever found yourself scratching your head, wondering whether to go with CNC machining or die casting for your next project? Well, you’re in luck! We’re about to dive deep into the world of metal manufacturing and help you find your perfect match. Buckle up, because this ride’s going to be as exciting as a rollercoaster in a machine shop!

The Manufacturing Matchmaking Game

First things first, let’s get to know our contestants:

In the blue corner, we have CNC Machining – the precision powerhouse! And in the red corner, Die Casting – the high-volume hero!

Both these manufacturing methods are like the superheroes of the industrial world, each with their own unique superpowers. But before we pit them against each other, let’s get to know them a little better.

Meet CNC Machining: The Swiss Army Knife of Manufacturing

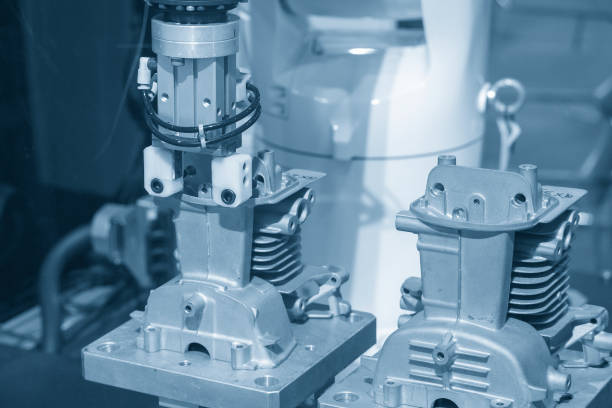

Imagine having a robot with the precision of a surgeon and the creativity of an artist. That’s CNC machining for you! Short for Computer Numerical Control, this process is like sculpting, but instead of chisels, we use high-tech cutting tools guided by computer programs.

What makes CNC machining so cool?

Precision that’ll make your jaw drop: We’re talking accuracies that would make a NASA engineer proud! Material flexibility: From metals to plastics, if you can dream it, CNC can probably machine it. Complex designs? Bring ’em on: With multi-axis capabilities, CNC machines can tackle designs that would make Picasso scratch his head.

Say Hello to Die Casting: The Master of Mass Production

Now, picture a process that can churn out parts faster than you can say “manufacturing marvel.” That’s die casting in a nutshell. It’s like making ice cubes, but instead of water, we’re using molten metal, and instead of an ice tray, we have a precision-engineered mold.

Why is die casting such a big deal?

Speed demon: Once we get rolling, parts come out faster than you can count them. Smooth operator: Die-cast parts often come out with a finish smoother than a jazz saxophone solo. Cost-effective for big batches: The more you make, the cheaper each part gets. It’s like buying in bulk, but for manufacturing!

The Showdown: CNC Machining vs. Die Casting

Now that we’ve met our contenders, let’s see how they stack up against each other. It’s time for the ultimate face-off!

Round 1: Material Versatility

CNC Machining: This process is like that friend who gets along with everyone. Metals, plastics, composites – you name it, CNC can probably work with it. Die Casting: A bit pickier, die casting prefers to hang out with non-ferrous metals like aluminum, zinc, and magnesium. It’s got a smaller circle of friends, but they’re all pretty cool.

Round 2: Cost and Setup Time

CNC Machining: It’s ready to go at a moment’s notice, but the meter’s always running. The longer it takes to machine a part, the more it costs. Die Casting: It’s like planning a big party. There’s a lot of upfront cost and preparation, but once the party starts, everyone can join in cheaply!

Round 3: Precision and Accuracy

CNC Machining: If precision were an Olympic sport, CNC machining would be taking home the gold. It’s all about those tight tolerances! Die Casting: While not quite as precise as its CNC counterpart, die casting still produces parts accurate enough for most applications. It’s like horseshoes – close enough often counts!

Round 4: Surface Finish and Post-Processing

CNC Machining: The finish can vary depending on the tool used. Sometimes, parts might need a little extra TLC after machining. Die Casting: Often produces parts smoother than a freshly waxed car. However, like anything in life, it’s not always perfect – sometimes surface defects can pop up if the die isn’t maintained properly.

Round 5: Production Speed and Volume

CNC Machining: It’s like a gourmet chef, crafting each part individually. Great for small batches, but can be slower for large-scale production. Die Casting: Once it gets going, it’s like a production line at a fast-food restaurant – churning out identical parts faster than you can say “Would you like fries with that?”

Round 6: Design Complexity

CNC Machining: If your design looks like something out of a sci-fi movie, CNC machining’s got your back. It can handle complex geometries that would make other processes wave the white flag. Die Casting: Prefers to keep things a bit simpler. It’s best for parts with uniform wall thickness and less complex geometries.

Choosing Your Manufacturing Soulmate

So, after all that, how do you choose between these two manufacturing heartthrobs? Well, it all comes down to what you’re looking for in a relationship… err, I mean, a manufacturing process.

Go steady with CNC Machining if:

You need parts so precise they could split a hair. You’re in the prototype phase or need a small batch of parts. Your design is more complex than a Rubik’s Cube.

Fall in love with Die Casting if:

You need to make more parts than there are fish in the sea. Surface finish smoother than a pick-up line is your thing. You’re looking to keep costs down on large production runs.

The Final Word: It’s Not You, It’s My Manufacturing Needs

Remember, there’s no one-size-fits-all in manufacturing. Both CNC machining and die casting have their strengths, and the best choice depends on your specific project needs. It’s like choosing between coffee and tea – they’re both great, but which one you prefer depends on your taste and the situation.

At GCH Process, we’re like manufacturing matchmakers

We’ve got years of experience playing Cupid with CNC machining and die casting, and we’re here to help you find your perfect manufacturing match. Whether you need the precision of CNC machining or the high-volume efficiency of die casting, we’ve got you covered.

So, what do you say? Ready to start your manufacturing love story? Reach out to our team, and let’s turn your production dreams into reality. After all, in the world of manufacturing, happily ever after is just a perfectly made part away!