In modern manufacturing, selecting the right CNC machining company is key to improving production efficiency. Whether it’s automotive parts, medical devices, or consumer electronics, CNC machining plays a crucial role across various industries. So, how do you find the most suitable partner among numerous suppliers? Let’s delve into this topic and analyze the key factors in choosing a CNC machining company from multiple perspectives.

Professional Experience and Technical Strength: The Foundation of Quality Partnership

When you start looking for a suitable CNC machining supplier, the primary consideration is the company’s experience and technical level. Rich experience translates to better understanding of needs and professional advice, not only efficiently completing tasks but also providing optimization solutions during the production process, helping you save time and costs.

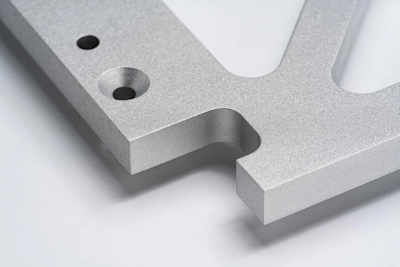

Many professional CNC machining companies continuously invest in the latest technology and equipment, ensuring they can machine various complex parts. Whether it’s multi-axis machining, micro-part production, or handling materials such as aluminum, stainless steel, and plastics, high-level CNC machining companies can meet various requirements.

Quality Control: The Key Link in Ensuring Production Efficiency

When choosing a CNC machining company, quality control is an important factor that cannot be overlooked. No one wants to receive substandard parts, which not only wastes time but also increases production costs. Therefore, finding a CNC machining company with a comprehensive quality control system is crucial.

Quality companies typically employ rigorous quality inspection processes, using advanced testing equipment such as Coordinate Measuring Machines (CMM) and laser scanners to precisely measure the dimensions of each part, ensuring compliance with design specifications. Additionally, many high-quality CNC machining companies have international certifications such as ISO9001, proving that their production standards meet globally recognized quality systems.

Diversified Machining Capabilities: Flexible Choices to Meet Different Needs

Different projects have different requirements, and choosing a company that offers a variety of machining services can provide greater flexibility. Excellent CNC machining companies typically offer comprehensive machining services, including CNC milling, turning, drilling, and grinding. This comprehensive machining capability allows you to complete all production needs in one place, eliminating the need to find multiple suppliers.

Moreover, outstanding companies can handle various materials, from common aluminum, copper, and stainless steel to more challenging high-performance materials like titanium alloys and plastics. If your project involves multiple materials, finding a partner with such diverse machining capabilities will greatly simplify your production process.

Customized Services and Flexibility: Key to Adapting to Market Changes

In a rapidly changing market, many companies require customized parts and flexible production cycles. Excellent CNC machining service providers should be able to quickly adjust production lines according to customers’ special needs. Whether it’s small-batch prototyping or large-scale production orders, flexible CNC machining companies can meet your needs.

It’s worth noting that customized services are not limited to parts machining but also include design and process optimization. Outstanding CNC machining companies can work closely with customers, providing technical support and design optimization to ensure that each part not only meets standards but also improves overall production efficiency.

Quick Response and Quality Customer Service: Guarantee of Successful Cooperation

When working with CNC machining companies, communication and response speed are equally important. Regardless of project size, you want partners who can quickly respond to questions and provide professional advice. Excellent CNC machining suppliers not only provide high-quality products but also offer quality pre-sales and after-sales services to customers.

For example, at the start of a project, the customer service team can help answer questions about material selection, process design, etc. During the production process, good communication ensures projects are completed on time, avoiding delays caused by miscommunication. Choosing a company that values customer service will make the entire collaboration process smoother.

Global Supply Chain and Logistics Capabilities: The Foundation for International Cooperation

Today, many CNC machining companies have established global supply chains to provide efficient machining services and timely delivery to global customers. Choosing a CNC machining company with global logistics capabilities not only ensures you receive high-quality products but also enjoy fast shipping and reliable delivery times.

Some excellent companies even offer customized logistics solutions, ensuring that projects can proceed as planned no matter where you are. This global perspective is particularly important for multinational corporations or companies with international business.

Innovative Technology and Equipment Upgrades: Key to Enhancing Competitiveness

When choosing a CNC machining company, consider their investment in innovative technology. For example, GCH Machinery focuses on the remanufacturing of CNC grinding machines, transforming old or worn machines into fully functional modern systems. This process includes comprehensive assessment, disassembly, replacement or repair of key components, and installation of the latest CNC control technology to improve precision and productivity.

The main advantages of GCH’s remanufacturing process include:

Cost savings: Compared to purchasing new equipment, remanufacturing can significantly save costs while providing performance comparable to new machines.

Customization: GCH offers the ability to customize machines according to specific needs, including integrating advanced automation features to optimize production lines.

Performance improvement: Remanufactured machines often surpass original specifications, providing higher precision, productivity, and consistency.

Extended machine life: Replacing worn parts and upgrading technology can significantly extend the life of machines.

These services are particularly suitable for industries such as automotive, aerospace, and medical device manufacturing, where precision and efficiency requirements are extremely high.

Conclusion: Choosing the Best CNC Machining Partner

Choosing the right CNC machining company involves not only considering reasonable prices but also evaluating their professional experience, quality control, flexibility, and customer service level. By selecting a CNC machining supplier with rich experience, excellent technology, and thoughtful service, you can ensure that each part meets the highest standards, reduce production risks, and improve overall production efficiency.

Whether your project involves small-batch custom parts or large-scale industrial production, a reliable CNC machining supplier is key to success. By partnering with the right collaborator, you will receive high-quality machining services, ensuring products are delivered on time and meet expectations. During the selection process, comprehensively consider the above factors, combine them with your specific needs, and you will surely find the most suitable CNC machining company to provide strong support for your business development.