Introduction

CNC (Computer Numerical Control) precision machining is a cutting-edge manufacturing process that involves the automated removal of material from a workpiece using specialized tools. This technique is essential for producing high-precision components with exacting tolerances. China, as a leading player in the global manufacturing sector, has a significant share in the CNC precision machining market. This article explores the intricacies of precision machining, China’s leading role, and the factors distinguishing Chinese manufacturers.

Understanding CNC Precision Machining

What is CNC Precision Machining?

CNC precision machining involves using computer-controlled machines to create parts with remarkable accuracy and consistency. Unlike traditional machining, which relies on manual adjustments, CNC machines follow pre-programmed codes, allowing for precise control over the manufacturing process. This level of precision is crucial for producing components that meet strict specifications.

Process Overview

- 3D Modeling: The process begins with designing a detailed 3D model of the component using CAD (Computer-Aided Design) software. This model acts as a blueprint for machining and requires careful design considerations to simplify subsequent operations.

- Programming: The 3D model is converted into machine-readable code using CAM (Computer-Aided Manufacturing) software. This code, including G-code and M-code, directs the CNC machine on how to perform the machining tasks.

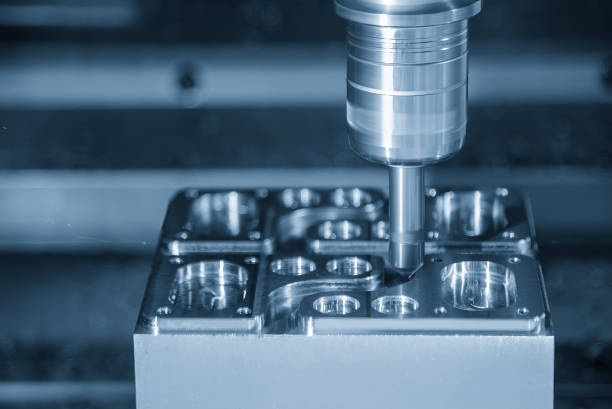

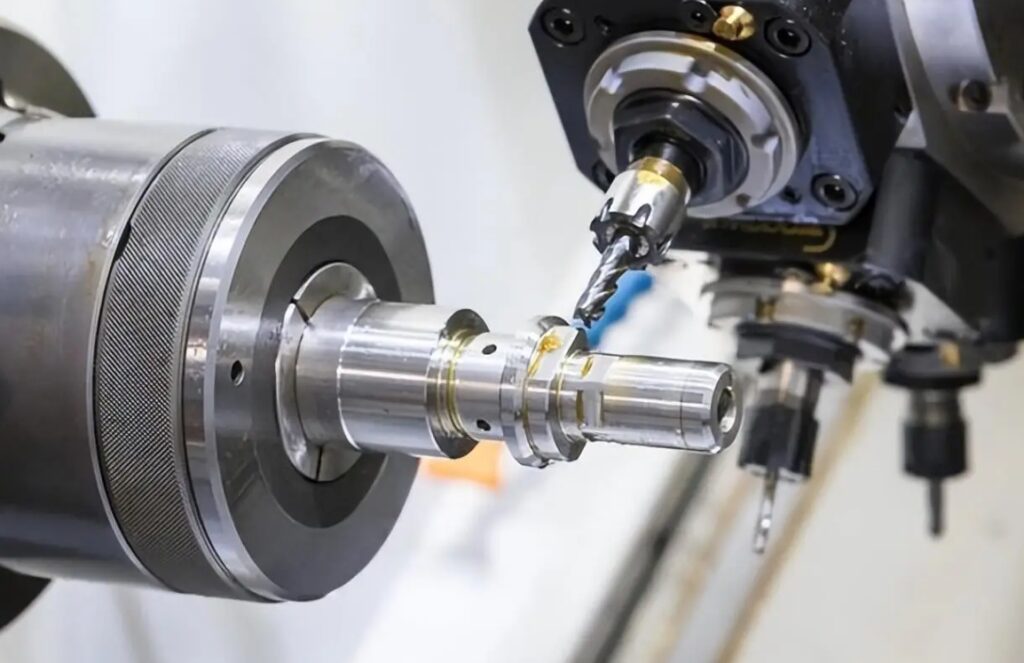

- Cutting: The workpiece is secured in the CNC machine, and the programmed code is executed. The machine uses various tools to cut away material to achieve the desired shape and dimensions. Advanced CNC machines, such as 5-axis and 7-axis models, offer enhanced automation and precision.

Types of CNC Precision Machining Technologies

Several CNC machining technologies are used based on the requirements of the component. These include:

- Milling Machines: For cutting and shaping materials with rotary cutters.

- Lathes/Turning Machines: For creating cylindrical parts through rotational cutting.

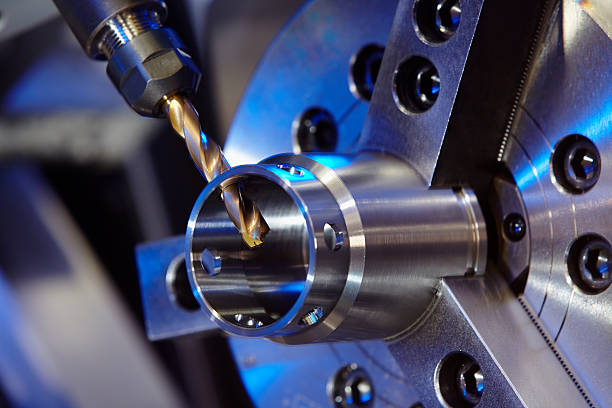

- Drills: For creating precise holes.

- Grinders: For achieving smooth finishes and tight tolerances.

- Boring Machines: For enlarging holes and achieving accurate internal diameters.

- Routers: For carving complex shapes in materials like wood and plastic.

- Laser Cutters: For high-precision cuts using laser technology.

- Electrical Discharge Machining (EDM): For cutting and shaping conductive materials using electrical sparks.

- Plasma Cutters: For cutting metal with a high-temperature plasma torch.

Each technology plays a crucial role in producing parts with specific geometric and material requirements. Often, multiple technologies are used together to achieve the desired result.

Advantages of CNC Precision Machining

CNC precision machining offers numerous benefits compared to traditional manufacturing methods:

- High Accuracy and Consistency: CNC machines produce parts with extreme precision, often within micrometer tolerances, ensuring that components meet stringent specifications.

- Complex Geometries: Capable of creating intricate shapes and features that are difficult to achieve manually, CNC machining is essential for industries requiring complex parts.

- Enhanced Dimensional Stability: CNC-machined parts exhibit excellent dimensional stability, critical for applications involving tight tolerances and high performance.

- Reduced Labor Requirements: The automation involved reduces the need for manual intervention, lowering labor costs and minimizing human errors.

- Faster Production Times: CNC machines operate efficiently, leading to quicker turnaround times for production runs.

China’s Position in the Global CNC Precision Machining Market

Market Share and Influence

China has become a dominant player in the CNC precision machining market. According to a GlobeNewswire report, the global CNC precision machining tools market was valued at $74.31 billion in 2018 and is projected to reach $109.39 billion by 2026. A significant portion of this market share is held by Chinese manufacturers, who are pivotal in the global supply chain for CNC machined parts.

China’s influence spans several industries, including electronics, automotive, aerospace, and defense. Chinese manufacturers supply approximately 90% of the world’s electronic machined components, emphasizing their crucial role in the global market. Additionally, the automotive sector heavily relies on Chinese precision machining, and the aerospace and defense industries also depend on Chinese-manufactured components for their critical applications.

Technological Advancements and Capabilities

China’s success in CNC precision machining is driven by technological advancements and skilled labor. The country has invested in state-of-the-art CNC machines and facilities, enabling the production of complex and high-precision components. Chinese manufacturers have adopted advanced CNC technologies, such as multi-axis machines and automation systems, enhancing their machining capabilities and efficiency.

Choosing a CNC Precision Machining Manufacturer in China

Key Considerations

When selecting a CNC precision machining manufacturer in China, consider the following factors:

- Experience and Expertise: Choose a manufacturer with a proven track record of delivering high-quality components and a deep understanding of CNC machining processes.

- Technological Capabilities: Assess the manufacturer’s technological capabilities, including the types of CNC machines and technologies they use. Advanced machines can significantly impact the quality and precision of the finished parts.

- Quality Control: Ensure the manufacturer has robust quality control measures, including advanced QA test equipment and a dedicated team for inspecting and verifying the dimensions and quality of machined parts.

- Production Capacity and Flexibility: Evaluate the manufacturer’s production capacity and ability to handle various project sizes and complexities. Flexibility in production capabilities is crucial for meeting tight deadlines and accommodating high-mix, low to medium volume projects.

- Cost and Lead Time: Consider the cost and lead time associated with the manufacturer’s services. A good manufacturer will offer competitive pricing while maintaining high quality and timely delivery.

GCH Process: A Leader in CNC Precision Machining

Company Overview

GCH Process is a premier CNC precision machining manufacturer based in China, renowned for delivering high-quality machined components across various industries. Our commitment to excellence and focus on technological innovation set us apart as a leader in the CNC machining sector.

Advanced Technology and Capabilities

At GCH Process, we operate a state-of-the-art machining facility equipped with the latest CNC machines and technologies. Our shop includes multi-axis machines, such as 5-axis and 7-axis models, allowing us to handle complex and precision-driven projects with ease. Our advanced equipment ensures we meet the demanding requirements of industries like automotive, aerospace, and electronics.

Expert Team and Quality Assurance

Our skilled team of professionals is dedicated to providing top-notch machining services. With extensive experience in CNC machining and a thorough understanding of industry standards, our team ensures high-quality outcomes. We have implemented rigorous quality control procedures to maintain the highest standards of precision and reliability.

Flexible Production and Competitive Pricing

GCH Process is equipped to handle a wide range of production volumes, from high-mix, low to medium volume projects to large-scale manufacturing runs. We offer competitive pricing and efficient lead times, delivering excellent value for our clients.

Conclusion

China’s leadership in CNC precision machining highlights the country’s technological advancements and manufacturing prowess. As a leading CNC precision machining manufacturer, GCH Process is committed to providing high-quality components and exceptional service. Our cutting-edge technology, skilled team, and dedication to quality make us a trusted partner for your precision machining needs. Contact us today to learn more about our services and discuss your project requirements.