CNC Machining for Renewable Green Energy Industry: Exploring Applications and Advantages

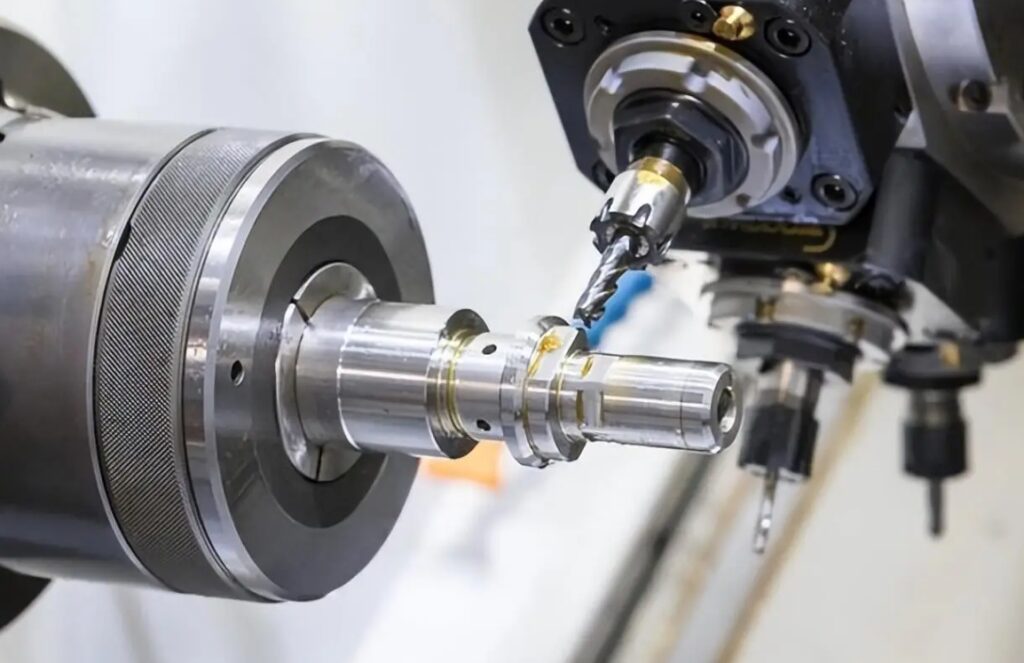

As the global push for sustainable energy solutions intensifies, the renewable green energy industry is experiencing unprecedented growth. Central to this transformation is CNC machining, a technology that has revolutionized the manufacturing of precision components. CNC (Computer Numerical Control) machining, with its computer-controlled precision, plays a vital role in the development and production of components for the renewable energy sector. Let’s dive into the specific applications and benefits that CNC machining brings to this innovative industry.

Key Applications of CNC Machining in Renewable Energy

- Wind Energy

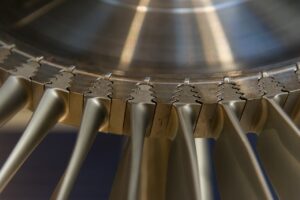

- Turbine Components: CNC machining is indispensable in manufacturing critical components of wind turbines, including hubs, rotor blades, and nacelle frames. The precision and reliability of CNC-machined parts ensure these turbines operate efficiently and have long service lives.

- Gearboxes: High-precision gearboxes in wind turbines rely on the accuracy and consistency provided by CNC machining, resulting in optimal performance and reduced maintenance requirements.

- Solar Energy

- Solar Panel Frames: CNC machining produces robust frames for solar panels, ensuring they can withstand harsh environmental conditions.

- Heat Sinks and Mounts: CNC-machined heat sinks and mounts are essential for the thermal management of solar inverters and other electronic components, enhancing the overall efficiency and durability of solar energy systems.

- Hydroelectric Energy

- Turbine Blades: The precision of CNC machining is crucial for manufacturing turbine blades used in hydroelectric power plants, ensuring high performance and efficiency.

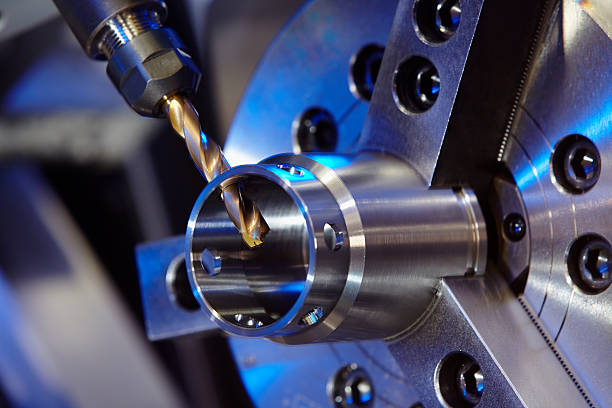

- Valve Components: CNC-machined valve components are vital for the reliability and durability of hydroelectric systems, contributing to the plant’s overall performance.

- Bioenergy

- Biofuel Production Equipment: CNC machining is used to create parts for biofuel production equipment, such as pumps, mixers, and reactors, ensuring they operate efficiently and reliably.

- Biogas Components: Components for biogas plants, including digesters and gas storage tanks, benefit from the precision and robustness provided by CNC machining, enabling them to withstand demanding operational conditions.

Advantages of CNC Machining for the Renewable Energy Sector

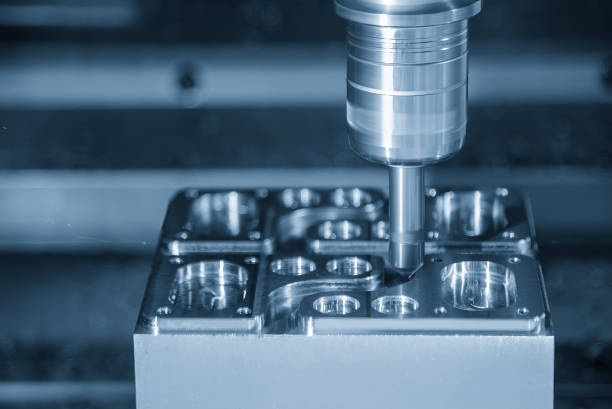

- Precision and Accuracy CNC machining offers unmatched precision and accuracy, critical for manufacturing components that meet stringent industry standards. The high level of detail ensures parts fit together seamlessly and function optimally, which is crucial for renewable energy applications.

- Efficiency and Consistency CNC machining’s automated nature allows for high repeatability and consistency, essential for producing large quantities of parts with uniform quality. This efficiency is vital for the renewable energy sector, where reliability and performance are paramount.

- Material Versatility CNC machining can work with a wide range of materials, including metals like aluminum, stainless steel, and titanium, as well as various plastics. This versatility enables the production of diverse components needed across different renewable energy applications.

- Cost-Effectiveness While the initial setup for CNC machining can be expensive, the process is cost-effective in the long run due to reduced waste, lower labor costs, and increased production speeds. This cost-efficiency benefits the renewable energy industry, often operating under tight budget constraints.

- Customization and Flexibility CNC machining allows for easy customization and adaptation of designs, making it ideal for prototyping and producing specialized components tailored to specific renewable energy applications. This flexibility fosters innovation and the continuous improvement of renewable energy technologies.

- Sustainability CNC machining aligns with the goals of the renewable green energy industry by minimizing material waste and energy consumption during manufacturing. The precision of CNC machining reduces the need for rework and scrap, contributing to more sustainable production practices.

GCH Process: Your Partner in Precision CNC Machining

At GCH Process, we understand the critical role of precision in manufacturing components for the renewable energy sector. With over [mention years of experience], we specialize in CNC machining services that meet the highest standards of quality and reliability. Whether you need turbine components for wind energy, frames for solar panels, or specialized parts for bioenergy applications, our expertise ensures your components are manufactured with precision and efficiency. Partner with GCH Process today and let us support your journey towards sustainable energy solutions.

Conclusion

CNC machining is a cornerstone technology in the renewable green energy industry, offering the precision, efficiency, and versatility needed to manufacture critical components. Its applications span across various renewable energy sectors, including wind, solar, hydroelectric, and bioenergy, supporting the industry’s growth and technological advancements. By leveraging the benefits of CNC machining, the renewable energy sector can continue to develop more efficient, reliable, and sustainable energy solutions, driving us towards a greener future.