Can the Titanium Processing Center Maximize Efficiency and Quality in CNC Machining? In the realm of CNC machining and manufacturing, titanium holds a prestigious status, often perceived as a benchmark due to its use in high-profile applications like NASA. This metal is renowned for its strength and unique properties, making it a preferred choice in various industries despite its challenges.

Why Titanium Matters in CNC Machining

Titanium boasts exceptional strength-to-weight ratio and biocompatibility, crucial for industries like aerospace and medical sectors. It can withstand extreme temperatures and is biologically inert, making it ideal for applications where reliability and safety are paramount.

Steel vs. Titanium in CNC Machining

While titanium offers superior strength at extreme temperatures and exceptional pliability, it presents significant challenges in CNC machining. It demands precise adjustments in tooling, feeds, and speeds due to its unforgiving nature, which contrasts sharply with the more forgiving characteristics of steel.

Cost Considerations

However, the benefits of titanium come at a cost—literally. It is significantly more expensive than steel, making it essential to optimize machining processes to maximize efficiency and minimize waste.

Learn how we processing the titanium metal .

GCH Process: Your Partner in Titanium CNC Machining

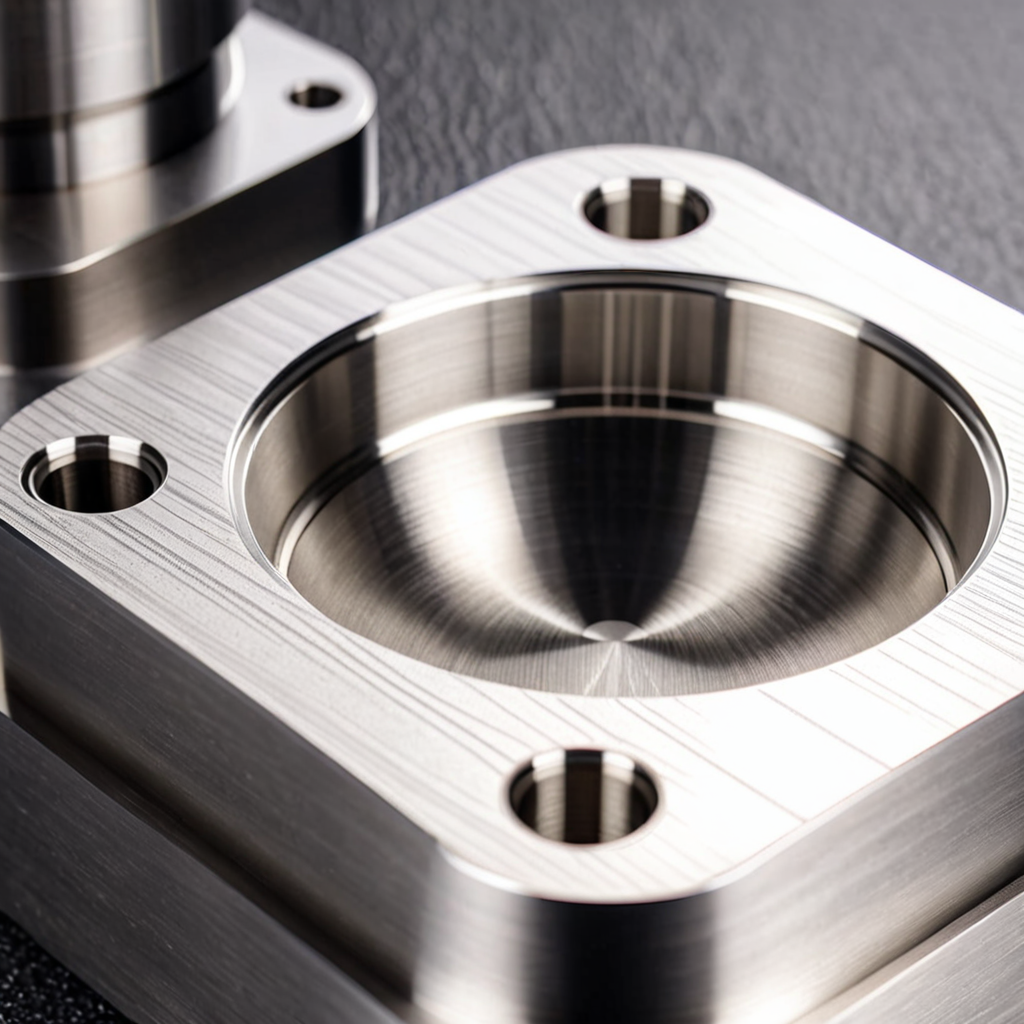

At GCH Process, we understand the complexities of titanium processing. Our CNC machining capabilities ensure precision and quality, whether you’re crafting components for aerospace, medical implants, or other critical applications. Our expertise in adjusting tooling and optimizing machining parameters ensures superior surface finishes and extends tool life.

Conclusion

While titanium presents challenges, its unique properties justify its use in critical applications. At GCH Process, we excel in overcoming these challenges, delivering high-quality titanium components that meet stringent industry standards. Trust us to elevate your CNC machining projects with our expertise and commitment to excellence.

Explore Titanium Processing with GCH Process

Watch how we excel in titanium machining with our advanced CNC capabilities. Contact us today to discuss your titanium machining needs and experience the GCH Process difference.

Reference: CNC MATERIALS: THE TRUTH ABOUT TITANIUM

Learn More About Titanium Processing

For more insights into optimizing titanium machining processes, watch our video showcasing our precision in titanium CNC milling with real-world examples.