Precison Machining Services

Get superior-quality precision CNC machining services for prototypes and production parts. Take advantage of advanced manufacturing solutions with competitive rates and short lead times.

- IATF16949:2016 certificated

- Lead time as fast as 3-5 days

- Tight Tolerance of 0.01 mm

- Milled Parts as Fast as 1 Day

- 3, 4, 5 Axis Milling

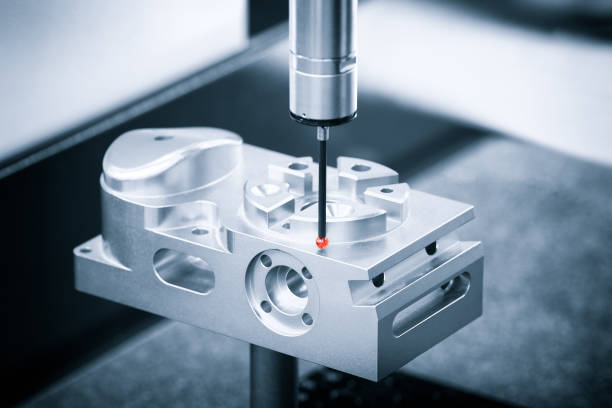

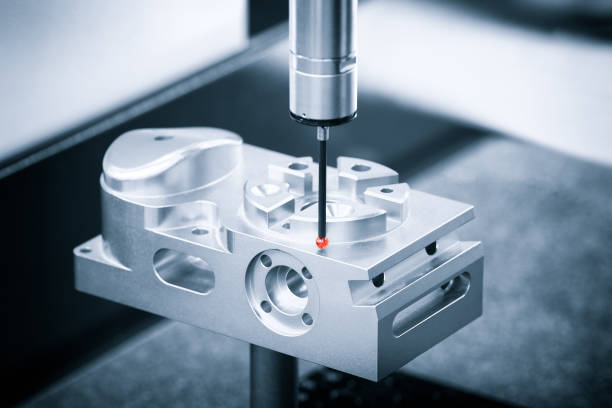

Precision CNC Machining Capabilities

WIRE EDM

GCH’s wire EDM, part of our CNC services, efficiently crafts both simple and intricate shapes. Ideal for parts requiring high precision, this no-contact method produces minimal burrs and excels with metals like steel and titanium. Favored in aerospace, automotive, and electronics for their accuracy, we ensure tailored, precise solutions regardless of your needs.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

| Tolerance | ± 0.0001 inches (0.0025 mm) or better (based on material and thickness) |

| Maximum Workpiece Size | Length: 16 inches (400 mm) Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

| Cutting Speed | Up to 300 mm2/min (specific to material and thickness) |

| Surface Finish | As fine as Ra 0.2 µm |

| Maximum Cutting Thickness | Up to 12 inches (300 mm) – varies based on material |

| Wire Diameter Range | 0.004 inches (0.1 mm) to 0.012 inches (0.3 mm) |

MIRROR EDM

Mirror EDM delivers mirror-reflective, high-precision parts. Capable of producing intricate shapes with tight tolerances, it excels on hard materials where conventional tools falter. Catering to industries from aerospace to electronics, our Mirror EDM ensures unparalleled precision, capturing intricate contours and complex geometries consistently.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Titanium, Aluminum, Tool Steel, Copper |

| Surface Finish | Achievable down to Ra 0.05 µm or better (based on material and process parameters) |

| Tolerance | ± 0.00005 inches (0.0013 mm) or better (depending on material and thickness) |

| Maximum Workpiece Size | Length: 16 inches (400 mm)

Width: 12 inches (300 mm) Height: 8 inches (200 mm) |

| Maximum Cutting Thickness | Up to 10 inches (250 mm) – varies based on material |

GRINDING

GCH’s advanced manufacturing facility features high-precision grinding machines, perfect for manufacturing metal parts with tight tolerances. Our versatile grinding excels from small parts to complex geometries. The precision wheels provide controlled material removal, ensuring polished finishes. This efficiency reduces costs, wear, and errors. Trust our expert team to guide you to the ideal grinding solution for your project.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Ceramics, Carbides |

| Grinding Methods | Surface Grinding, Cylindrical Grinding, Centerless Grinding, Internal Grinding |

| Tolerance | ± 0.0001 inches (0.0025 mm) or better (specific to material and grinding method) |

| Maximum Workpiece Size | Length: 24 inches (600 mm)

Width: 10 inches (250 mm) Diameter: 8 inches (200 mm) for cylindrical grinding |

| Surface Finish | Achievable down to Ra 0.1 µm or better (based on material and grinding method) |

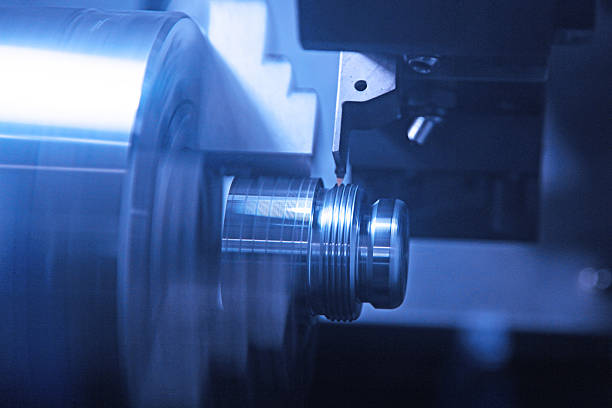

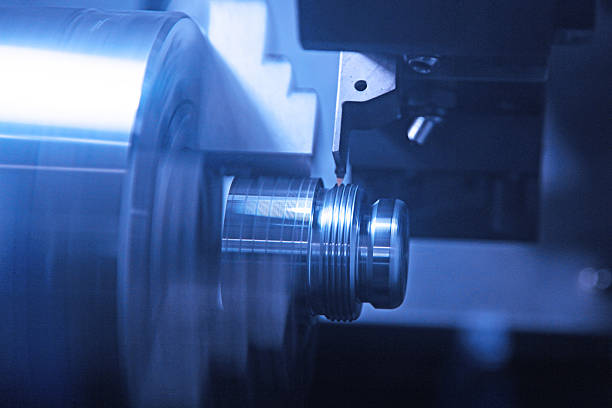

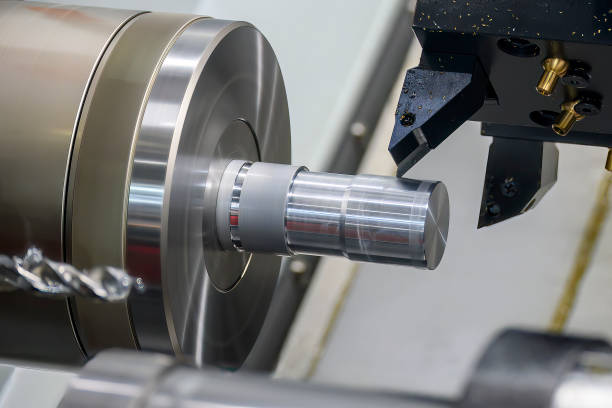

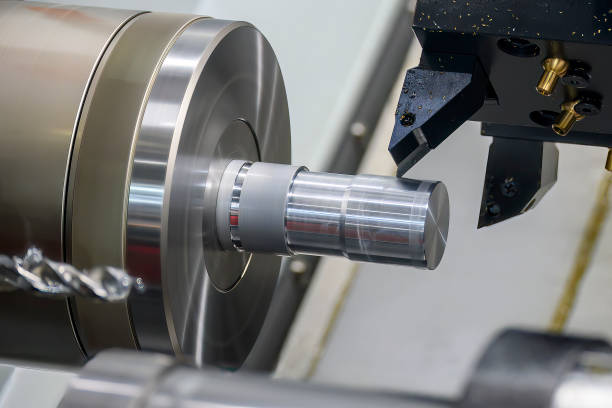

CNC TURNING

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics |

| Turning Operations | External & Internal Turning, Facing, Taper Turning, Boring, Drilling, Threading |

| Tolerance | ± 0.0005 inches (0.0127 mm) or better (specific to material and operation) |

| Maximum Workpiece Diameter | 20 inches (508 mm) or specific to machine capability |

| Maximum Workpiece Length | 60 inches (1524 mm) or specific to machine capability |

| Axis | 2-axis, 3-axis, multi-axis turning capability |

| Bar Feeding Diameter | Up to 3 inches (76 mm) or machine-specific |

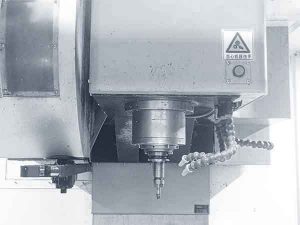

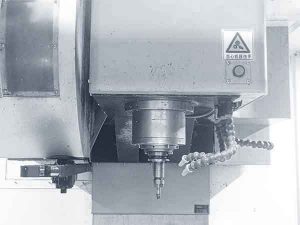

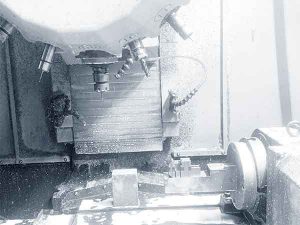

CNC MACHINING

GCH’s multi-axis milling machines guarantee CNC parts with tight tolerances and precise dimensions. This technology delivers precision tailored to your needs, ideal for iterations and new products. Compatible with a broad material range, from metals to composites, our CNC milling boasts efficiency, having parts ready swiftly.

| Capability | Details/Specifications |

| Material Compatibility | Stainless Steel, Aluminum, Tool Steel, Copper, Brass, Titanium, Plastics |

| Milling Operations | Face Milling, Profile Milling, Pocket Milling, Complex Surface Milling, Drilling, Boring |

| Tolerance | ± 0.0005 inches (0.0127 mm) or better (specific to material and operation) |

| Maximum Workpiece Size | X: 40 inches (1016 mm)

Y: 20 inches (508 mm) Z: 25 inches (635 mm) or specific to machine capacity |

| Axis | 2-axis, 3-axis, multi-axis turning capability |

| Bar Feeding Diameter | Up to 3 inches (76 mm) or machine-specific |

Precision Machining for Prototyping & Production

Accelerate your product development with GCH’S custom-machined prototypes and end-use products, delivered with utmost efficiency. Tailor your production needs by choosing the manufacturing volume and processes that perfectly align with your requirements. We guarantee swift turnaround times without compromising the quality of prototypes and production parts.

Precision Machined Part Size Standards

| Classification | Minimum Size (mm) | Maximum Size (mm) | Common Applications |

| Ultra-Precision Components | 0.1 | 1 | Watch components, micro devices |

| Micro Machined Parts | 1.1 | 10 | Medical devices, small electronics |

| Small Machined Parts | 10.1 | 50 | Aerospace, automotive sensors |

| Medium Machined Parts | 50.1 | 200 | Automotive, defense, industrial tools |

| Large Machined Parts | 200.1 | 1000+ | Heavy machinery, construction |

Precision CNC Machining Tolerances

| Operation Type | Typical Tolerance (mm) | Best Possible Tolerance (mm) | Notes |

| EDM (Electrical Discharge Machining) | ±0.015 | ±0.005 | Tolerance can be affected by electrode wear. |

| Grinding | ±0.005 | ±0.001 | Surface finish is typically smoother with grinding. |

| CNC Turning | ±0.025 | ±0.010 | Finish can impact tolerance. |

| CNC Milling | ±0.025 | ±0.005 | Precision can vary based on tool type and material. |

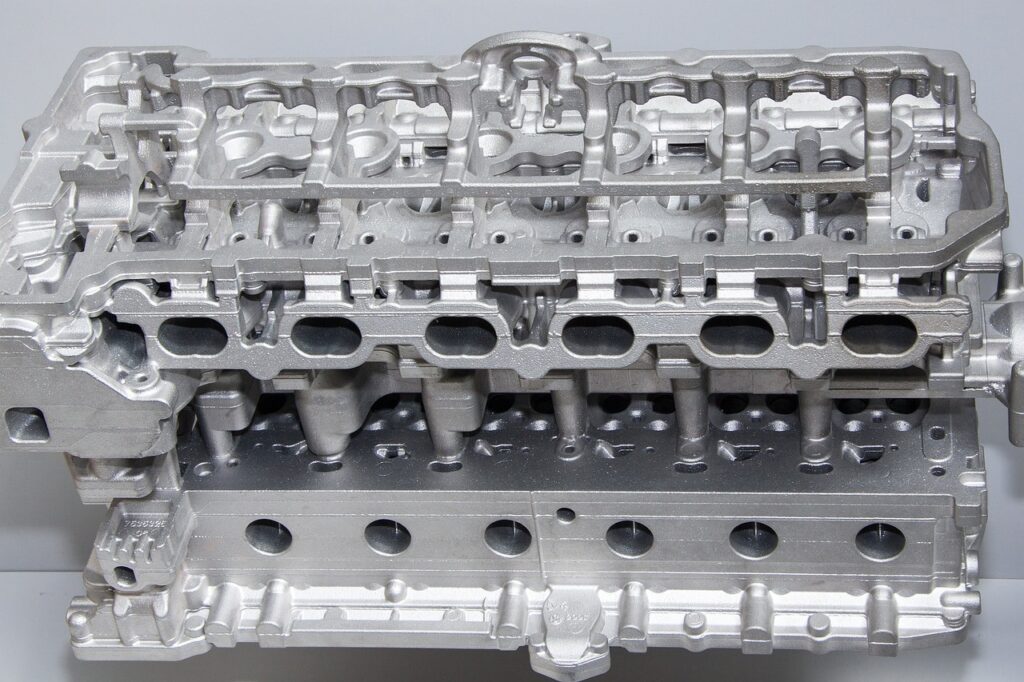

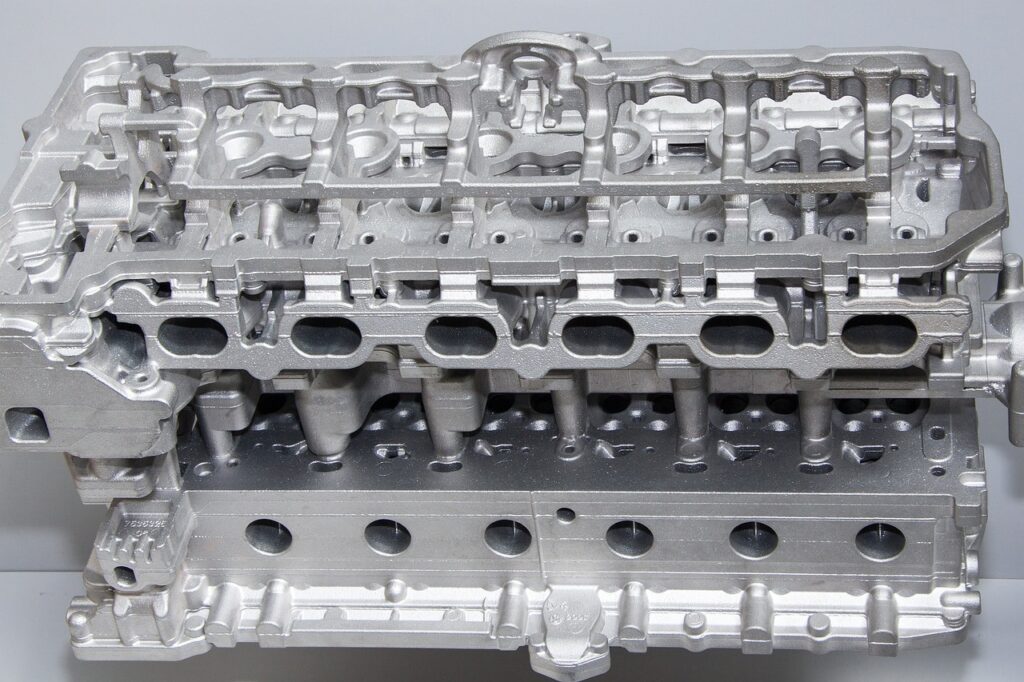

Gallery of Precision CNC Machining Parts

Why Choose Our Precision Machining Services

Transform your designs into reality with GCH’s top-notch precision machining services. We boast cutting-edge manufacturing capabilities that ensure high precision in all our machining processes. Every prototype and end-use part meets strict quality standards and tolerance requirements, delivering exceptional results for your projects.

High Precision and Tight Tolerances

Rapid Prototyping and Production

We expedite your product development from prototyping to production. Our quick turnarounds turn designs into prototypes, enabling faster iterations and reduced time-to-market. Our CNC machining is scalable to any production volume.

Advanced Manufacturing Facilities

At GCH, our comprehensive equipment includes Precision CNC milling, turning, and EDM. From prototypes to mass production, we use top materials and technology. Our dedicated technicians work tirelessly for optimal product quality.

IATF16949:2016 Certificated

GCH boasts expert engineers ready to optimize your designs, cut costs, and enhance quality. Trust our team for exceptional advice and unmatched engineering support, ensuring top-tier project results.

Materials for Precision Machining Services

At GCH, our precision machining service provides a wide range of materials, ensuring both precision and durability. This extensive selection empowers our clients with optimal choices for their unique projects, enhancing the quality and performance of their products.

Aluminum

Aluminum has an excellent strength-to-weight ratio of this metal. It is a great option for the high loading requirements of aircraft brackets and housings. Aluminum also boasts good ductility, stiffness, corrosion resistance, and machinability. Its lightweight properties make it useful for aerospace structural applications like fuselage skin, wing stringers, wing skins, etc.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

These properties make titanium alloys great options for airframes and aircraft engines.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Steel is another metal with application in the production of modern-day automobile parts. This metal is durable and efficient in performance. It also facilitates the production of high-quality parts. It is resistant to corrosion, lightweight, and results in the production of aesthetically pleasing parts. This metal has applications in the production of car brakes, engines, exhaust systems, wheels, etc.

Price: $

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Copper

Copper plays a huge role in comfort, efficiency, and safety in the automotive industry. It is an excellent conductor of electricity, highly ductile, and malleable. It has application in most of the vehicle’s electronic components, including vehicle’s wire harness, radiator, starter motor, alternator, and brake tubes.

Price: $

Lead Time: <10 days

Tolerances: ±0.125mm

Max Part Size: 200 x 80 x 100 cm

Magnesium

Magnesium is lightweight and has excellent castability and high specific strength, which gives it application in the automotive industry. Magnesium has applications in producing engine blocks, gearboxes, clutch housings, wheels and engine cradles, and oil pans.

Price: $

Lead time: <10 days

Tolerances: ±0.125mm

Max Part Size: 200 x 80 x 100 cm

Our Precision Machined Parts for Various Industrial Applications

At GCH, we prioritize the aesthetics and functionality of your precision CNC parts. Our diverse surface finishes ensure custom-tailored precision. Trust in our commitment to enhance your projects with lasting excellence.

- As-machined finish

- Anodizing

- Bead blasting

- Powder coating

- Polishing

- Polishing

- Passivation

- Brushed finish

Precision Machining Tolerances

At GCH, we guarantee precision through our strict tolerance standards for precision machining. We are committed to exact measurements, providing clients with consistent, high-quality results optimized for search visibility. Our standard tolerances for machined metals follow ISO 2768-m, while for plastics, we adhere to ISO 2768-c.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

Why Choose GCH

At GCH, we take a customized approach to meet your specific requirements. We provide long-term precision machining solutions for engineering experts and project managers, guiding you from design to production. GCH combines cost-effective machining processes with technology-driven services to deliver high-quality parts that meet your standards.

No MOQ

No minimum order requirement helps move plastic molded parts from design to production in a fast turnaround and supports your on-demand molding manufacturing needs with reduced injection molding cost.

Tight Tolerance and High Quality

Our plastic injection molding process includes vital design considerations to improve moldability and enhance aesthetic appearance. GCH delivers plastic injection molded parts of varying sizes and complexities. Our standard tolerances are defined by ISO 2768 standards, helping us meet tight tolerance requirements.

High Efficiency

With certified domestic factories and a strong supply chain system, we accelerate the product development cycle and bridge the production of your injection molded parts as fast as possible.

Injection Molding Specialists

Working with our experts having 10+ years of experience in the injection molding industry, efficiently complete a turnaround from prototyping to production.

Our Precision Machining Parts for Various Industrial Applications

GCH collaborates with top industry manufacturers to streamline supply chains through digitized custom precision machining. This partnership transforms ideas into tangible products efficiently, ensuring high-quality outcomes for every project.

Latest Posts

The Role Of CNC Machining In Modern Automotive Manufacturing

“CNC machining services for the automotive industry, offering high-performance, custom parts with precision engineering.”

The Advantages Of Aluminum In CNC Machining

High-precision CNC machining services for custom aluminum parts, ideal for aerospace, automotive, and industrial applications.

The Challenges Of Titanium CNC Machining And How To Overcome Them

Expert Titanium CNC Machining – Precision CNC machining of titanium parts for aerospace, medical, and industrial applications. High-quality custom parts manufacturing.