Exquisite Craftsmanship in Components, Forged with Exceptional Expertise.

Immerse yourself in the realm of our robust manufacturing prowess, where each service is finessed to fulfill your distinct prototyping and production requirements. Our technical acumen extends to state-of-the-art methodologies, including the precision artistry of CNC machining, the transformative magic of injection molding, the architectural grace of sheet metal fabrication, among others. Entrust us with the task of breathing life into your prototypes or components.

- 3000 + companies served

- 200,000 + unique parts produced

- 300 + suppliers cooperated

- Home

- Our Capabilities

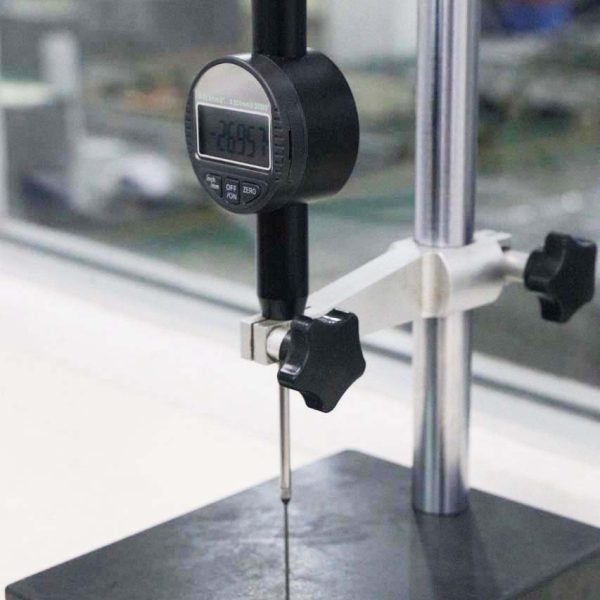

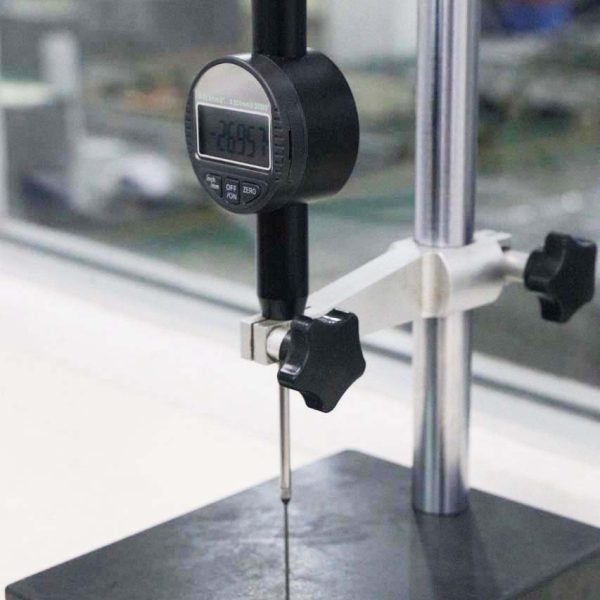

Unwavering Commitment to Crafting Superior Goods.

With a collective wisdom of 14 years, our squad of seasoned engineers meticulously scrutinizes and refines design blueprints. They’re dedicated to optimizing for stellar performance, budget-friendly solutions, and seamless mold production. Every design is meticulously examined, with a watchful eye on numerous critical aspects, guaranteeing the birth of molds that are truly exceptional in quality and craftsmanship.

Sharper focus, unparalleled professionalism.

- Wall Thickness

- Aesthetics

- Shrinkage

- Dimensional Stability

- Stress

- Cost

- Functionality

Aluminum

Aluminum has an excellent strength-to-weight ratio of this metal. It is a great option for the high loading requirements of aircraft brackets and housings. Aluminum also boasts good ductility, stiffness, corrosion resistance, and machinability. Its lightweight properties make it useful for aerospace structural applications like fuselage skin, wing stringers, wing skins, etc.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

These properties make titanium alloys great options for airframes and aircraft engines.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Steel is another metal with application in the production of modern-day automobile parts. This metal is durable and efficient in performance. It also facilitates the production of high-quality parts. It is resistant to corrosion, lightweight, and results in the production of aesthetically pleasing parts. This metal has applications in the production of car brakes, engines, exhaust systems, wheels, etc.

Price: $

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Copper

Copper plays a huge role in comfort, efficiency, and safety in the automotive industry. It is an excellent conductor of electricity, highly ductile, and malleable. It has application in most of the vehicle’s electronic components, including vehicle’s wire harness, radiator, starter motor, alternator, and brake tubes.

Price: $

Lead Time: <10 days

Tolerances: ±0.125mm

Max Part Size: 200 x 80 x 100 cm

Magnesium

Magnesium is lightweight and has excellent castability and high specific strength, which gives it application in the automotive industry. Magnesium has applications in producing engine blocks, gearboxes, clutch housings, wheels and engine cradles, and oil pans.

Price: $

Lead time: <10 days

Tolerances: ±0.125mm

Max Part Size: 200 x 80 x 100 cm

Thermoplastics

There are many types of thermoplastics with use in the automotive industry, including HDPE, Polypropylene, Acrylic, Polycarbonate, PPS, ABS, and PC-ABS. These thermoplastics have excellent properties, ranging from high impact resistance to the ability to resist high temperatures. PPS. For instance, it has excellent dimensional stability, temperature tolerance, and resistance to stiffness. You find thermoplastics in vehicle interiors, as well as battery frames and vehicle bumpers.

Bespoke Production at Your Command.

With our solid manufacturing skills, you can decide on the production quantity and other steps that fit your manufacturing requirements.

Rapid Prototyping

Low Volume Manufacturing

High Volume Manufacturing

Aerospace Manufacturing Capabilities

Take advantage of our professional manufacturing services throughout the production cycle, from prototyping and design validation to functional testing and product launch. We deliver high-quality and precise flight-worthy components with fast turnaround and at low costs. With our quality control process, you can be sure of getting parts that meet your unique requirements.

Actual People, Ready to Assist.

We provide exceptional support even after order completion, giving you the confidence to offer your products to your market. Expert technicians with over a decade of industry experience and vast product expertise assist you with troubleshooting and optimal product use.

Technical Support

Project Management