About Us

Why you need

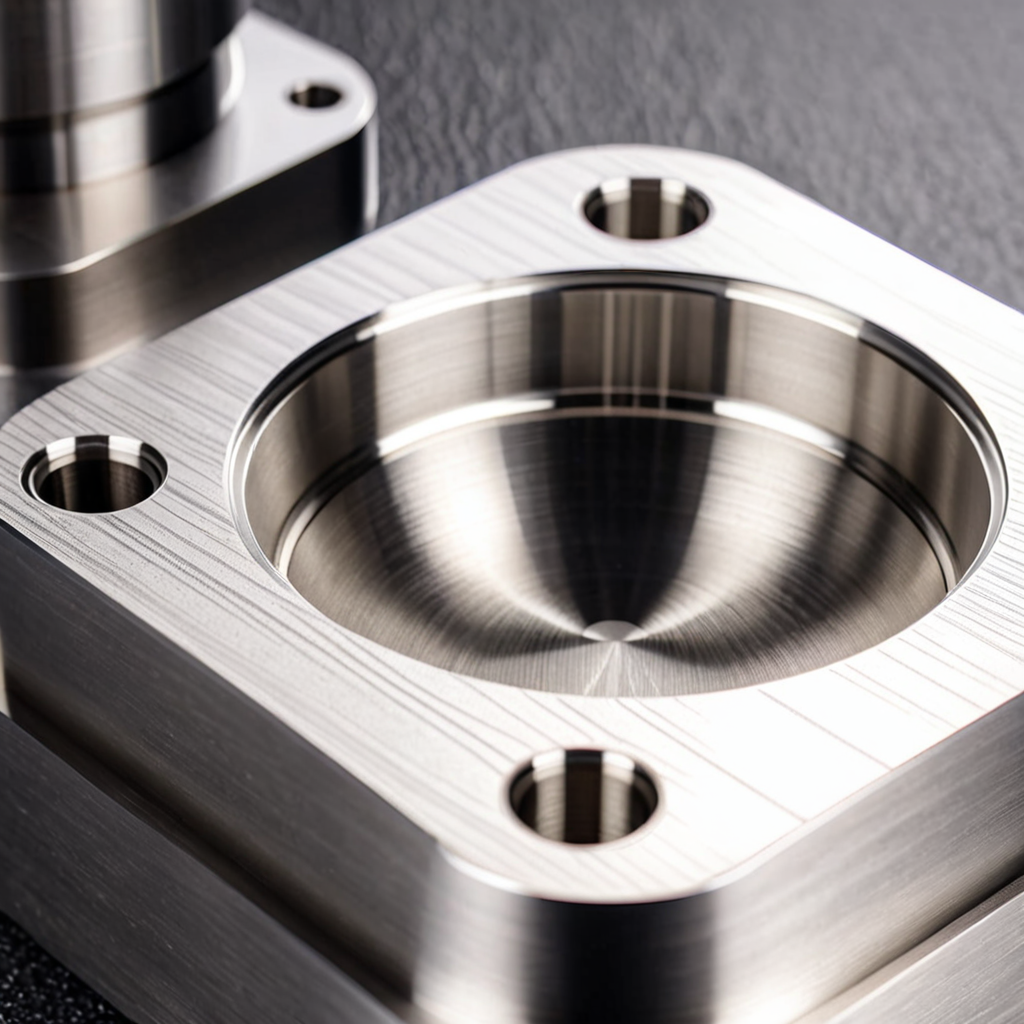

Our CNC machining

Services

At GCH Process, our team of experienced engineers is dedicated to delivering high-precision CNC machining solutions tailored to your unique project needs. From initial concept to final production, we support you at every stage of development, ensuring accuracy, efficiency, and quality in every part we produce.

To streamline your project initiation, simply upload your 3D CAD files, and our engineering team will promptly provide a detailed, competitive quote. With our advanced CNC machining capabilities and commitment to excellence, we’re here to help bring your designs to life with precision and reliability.

- IATF:16949 Certificate

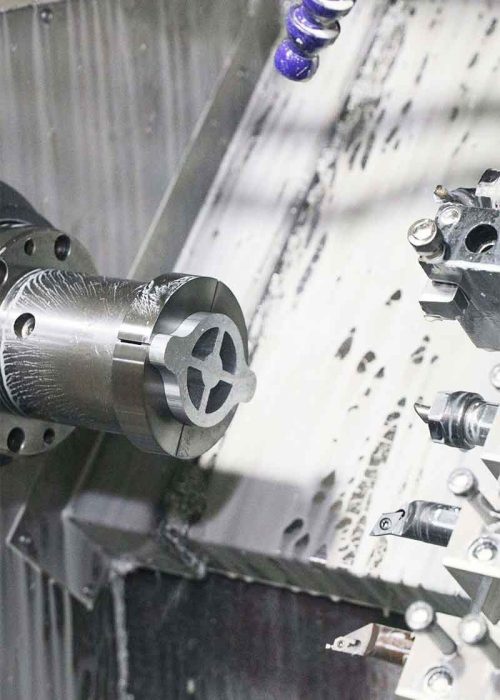

- 5-axis CNC machining workshop

- ISO9001:2015 quality control system

- A professional engineering team of more than 30 people

Since 2010

15

Years of

Practicing

Companies Served

Unique Parts Produced

Countries Shipped

Suppliers Cooperated

- Home

- About GCH

Our Mission

Bridge the gap between design and manufacturing

To create a technology-driven collaborative manufacturing platform that addresses the diverse needs of our customers while bridging the gap between design and manufacturing through partnerships with suppliers.

Our Milestone

Have a quick glance at how GHC CNC machining grew over the years – from our simple beginnings to our position as a trusted global manufacturer.

Hello World!

Found

In 2010, GCH was established, marking the beginning of its journey in the precision manufacturing industry. Located in the Xinfa Industrial Area of Xinqiao Street, Bao’an District, GCH quickly gained recognition in the industry due to its superior geographical location and convenient transportation.

February 2010

Expansion of the company's size

Grow

In 2012, GCH expanded its production scale by purchasing a batch of advanced equipment, including precision aluminum alloy die-casting machines, CNC lathes, and CNC machining centers. This allowed GCH to achieve one-stop production from raw materials to finished products, enhancing production efficiency and product quality.

March 2012

Obtained IOS9001:2015 certificate

Certification

In 2015, GCH obtained the ISO 9001:2015 quality management system certification, further standardizing its production processes and quality management, and ensuring the provision of high-quality products and services to its customers.

March 2015

Obtained IATF 16949:2016 certificate

IATF 16949:2016

In 2018, GCH successfully acquired the IATF 16949:2016 quality system certification and the QC080000 certification, further elevating its industry status and brand image. The company’s products began to be widely used in various fields such as automotive, telecommunications, and medical, achieving diversified business development.

May 2018

The company expanded again

continued to grow

By 2020, GCH continued to grow, employing over 160 staff, including more than 70 professional technicians. With a sound organizational structure and reasonable personnel allocation, GCH is able to promptly provide customers with the highest quality products and most comprehensive services. GCH has established a good reputation in both domestic and international markets, laying a solid foundation for the company’s sustainable development.

March 2020

To Know More About Us

Learn more about our factory and the strength of our customization through our company's live video.

The FAQ

Frequently Asked Questions

The costs associated with our CNC machining services are variable and directly affected by your project, including its design and tolerance specifications. The quantity of product machined is another key determinant of cost. For example, if you need a part with a combined machining and material cost of $2, plus an additional $200 for setup, the total cost of a single part would be $202. In contrast, if you commissioned 200 of the same part, the cost per part would be only $3!

Depending on the complexity of the design, the materials selected and GCH's current workload, lead times may vary. For example, over 90% of our current CNC machining orders are completed in about 7 days. Simple CNC machining parts can be completed in 2 days, while complex or large CNC machining parts can take upwards of 15 days. Transportation time is another issue to consider.

GCH is able to meet the needs of one-off mass production runs. In fact, we typically don't have strict minimum order quantities. Whether you need a single part or thousands, RapidDirect is designed to provide a solution to meet the needs of our customers.

GCH is one of the best CNC machining companies in China for quality, speed and customer service. With our high quality CNC machines, we can achieve tolerances up to within +/- 0.01 mm. Achieving this may have a cost impact depending on the highest level of accuracy required for your product.

GCH CNC services are highly compatible with the materials being processed and are therefore suitable for a wide range of applications. Our common CNC materials include steel, iron, copper, aluminum alloys, die-cast materials, POM, PP materials, PC sheets, PEEK, polyurethane and other metals. However, the availability of specific materials may vary, so it is best to contact the service provider directly.

Call Us 24/7

(86)134 3475 3902

rebecca@gchprocess.com