Professional CNC Machining Service ,Custom and Quality-Focused

- IATF16949:2016

- ISO9001:2015

- 100+ metals 50+ surface finishes

Our manufacturing capabilities

GCH Process is a leading in rapid prototyping, renowned for our reliability. We specialize in transforming your designs and ideas into fully functional parts in just a few days.

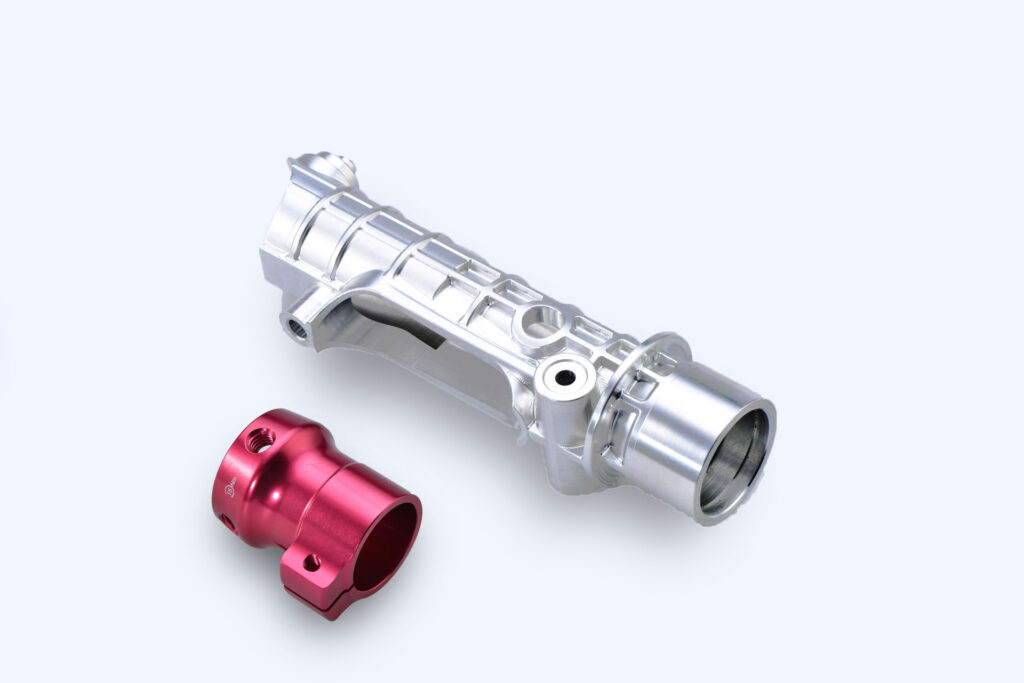

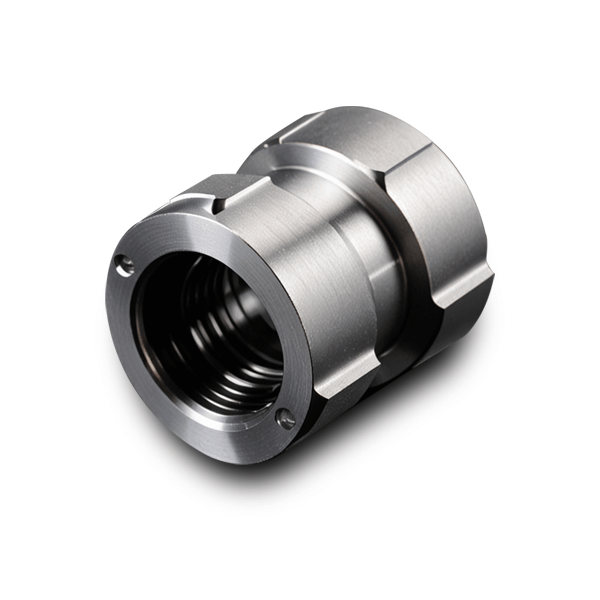

CNC Machining

Utilizing CNC milling and turning, GCH Process manufactures a wide range of prototypes and production parts tailored to meet your specific needs.

CNC Turning

Our expertise in CNC turning ensures the swift production of highly detailed elastomer plastic prototypes.

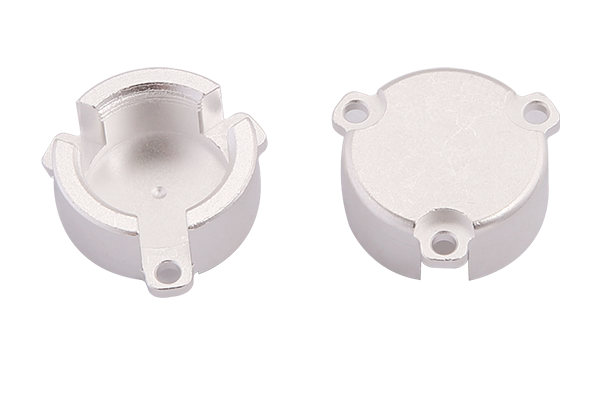

Die Casting

GCH Process offers both low-volume prototype moldings and mass production moldings to suit your project requirements.

Making prototype and parts delivery easier

Get 3-day standard lead times on simple parts sized between 10 mm x 10 mm and 200 mm x 200 mm. Upload your part to see if it’s eligible.

Upload Your CAD Files

Quote & Design Analysis

Order Confirmation

Parts Shipped

From Prototyping to Production

With many years of manufacturing experience, GCH offers the best solutions for all rapid prototyping and low-volume manufacturing needs. We streamline the innovation cycle into three simple but effective steps.

Rapid Prototyping

With our instant quotation platform and robust manufacturing capabilities, we can deliver exceptional prototypes within short lead times. This enables you to quickly test prototype parts and bring them to market faster.

Bridge Production

With our robust manufacturing capabilities, we can deliver exceptional prototypes within short lead times. This enables you to quickly test prototype parts and bring them to market faster.

On-Demand Production

With our instant quotation platform and robust manufacturing capabilities, we can deliver exceptional prototypes within short lead times. This enables you to quickly test prototype parts and bring them to market faster.

rapid prototypes and custom parts

GCH Process is the ideal partner for sourcing your rapid prototypes and custom parts.

We have a team of skilled engineers ready to support you in your product development journey from prototyping to production.

When you’re ready to start your next project, simply upload your 3D CAD design files, and our engineers will get back to you with a quote as soon as possible.

Why choose GCH as your CNC Machining Processor

Choose us as your CNC machining partner for precision, reliability, and fast turnaround, backed by years of expertise and cutting-edge technology to meet your most demanding manufacturing needs.

The trust of a major manufacturer

Our company is a cooperative factory of the world’s top 500 companies, we have advanced technology and perfect equipment and a very professional team to escort your customized journey.

- IATF16949:2016 Quality Management System Certification.

- ISO9001:2015 Quality Management System Certification.

- QC080000 System Certification

- Guangdong Province Contract-Abiding and Credit-Valuing Enterprise

- Shenzhen Key High-Tech Enterprise

Oversized plant, professional team

Our factory has a 5000+ square meters manufacturing workshop, as well as a team of more than 30 professional engineers, and very specialized equipment, which gives us a very professional ability to turn your industrial design into reality.

The company owns 24 CNC lathes, 50 CNC machining centers, 13 drilling and tapping machines, 7 milling machines, 8 wire cutting machines, gear machines,and a whole set of precision supporting equipment. To meet the precision requirements of products in various industries, our company is equipped with a batch of advanced testing equipment, such as fully automatic three-coordinate measuring machines, two-dimensional measuring instruments,etc.

Service Awareness Everywhere

As the world’s leading machining service provider, especially because of many years of CNC-related machining experience, so that we have accumulated a very large number of invaluable service experience, our purpose is the customer first, so we withdrew from the 24h/7day service model, so that our customers can find us at any time and any place and get professional support.

Quality Assurance Backed by Professional Experience and Expertise

As an ISO 9001:2015 certified and IATF:16949 certified firm, we rigorously adhere to ISO standards throughout our production processes to deliver products of consistently superior quality. Our rapid prototyping and manufacturing facilities are equipped with state-of-the-art technology, ensuring precision and uniformity in manufacturing. With advanced in-house testing and measuring equipment, we verify that each part meets your exact specifications.

Premier Technical Assistance

GCH, with its team of committed and skilled engineers and technicians, is equipped to address your issues with proactive and expert assistance around the clock.

- 1-on-1 Technical Support

- Professional Design Support

- Elite Engineers & Technicians

Strict Quality Assurance

We maintain a rigorous quality control system to guarantee the production of high-quality prototypes and end-use parts.

- ISO 9001 Certified Factory

- Strict Manufacturing Standards

- Advanced Facilities

Rework and Guarantee Policy

Should the parts not conform to the specified requirements, please notify us within five business days after receiving your order. We commit to resolving your issue within 1 to 3 business days.

- 30-Day-Guarantee

- Responsive Reply & Support

- Genuine After-sales Policy

Collaboration Across a Wide Range of Industries

From prototyping to production, GCH guarantees superior quality and dependable functionality. Utilizing CNC machining alongside a diverse selection of production-grade metal and plastic materials, and advanced on-demand manufacturing techniques, we deliver high-quality products across multiple industries.

Automotive

Our low-volume manufacturing services is the ideal manufacturing solution for on demand automotive parts.

Aerospace

The durability and precision that our precision manufacturing services provide meets the sophisticated needs the different phases of the aerospace industry required.

Consumer Goods

Collaborating with prominent consumer goods manufacturers allows us to expedite the prototyping phase and enhance the consumer goods industry’s overall performance.

Medical Devices

Our prototyping solutions offer substantial advantages to medical supply manufacturers, tech startups, and research laboratories.

Robotics

Our industrial-grade robotics prototyping and component fabrication services contribute to the ongoing development of the robotics industry.

Communication accessories

We have very mature and leading experience in 5G communication CNC parts processing, and have helped our customers take the lead in the communications industry.

See What Our Customers Say About Us

The testimonials of our clients carry more weight than our own assertions – witness the positive feedback our customers have shared about how we met and exceeded their expectations.

Want to make your design a reality?

Let's Start

A New Project Today

Contact our engineers immediately and we will quickly help you determine your best solution based on your needs.

Latest CNC Machining Posts

Check out the latest industry trends and take inspiration from our updated blogs, giving you a fresh insight to help boost your business.

Your Expert in Custom CNC Parts: One-Stop Solutions from Prototype to Mass Production

Introduction In today’s rapidly evolving manufacturing landscape, CNC (Computer Numerical Control) machining technology plays a pivotal role. From precision medical…

CNC Machining Manufacturer: The Backbone of Precision Engineering

Introduction CNC (Computer Numerical Control) machining has revolutionized the manufacturing landscape, becoming a cornerstone of precision engineering. This advanced technology…

Mastering CNC Machining: A Comprehensive Guide from Basics to Advanced Techniques

In a modern manufacturing facility in aerospace valley, a precisely engineered titanium component takes shape inside a sophisticated Computer Numerical…